Nuestro separador de fibras para el reciclaje de neumáticos es un sistema de purificación especializado diseñado para líneas de producción de polvo de caucho. Su misión central es separar y eliminar de forma eficiente las fibras de nylon y textiles que se entremezclan con el polvo de caucho. Como paso crítico instalado directamente después del molino de polvo de caucho, eleva la pureza de su polvo de caucho a un nuevo nivel, asegurando que el producto final cumpla con los más altos estándares de calidad. Para cualquier negocio dedicado a producir polvo de caucho reciclado de alto valor y grado premium, integrar un separador de fibras de alto rendimiento es una inversión esencial.

La Importancia de la Separación de Fibras

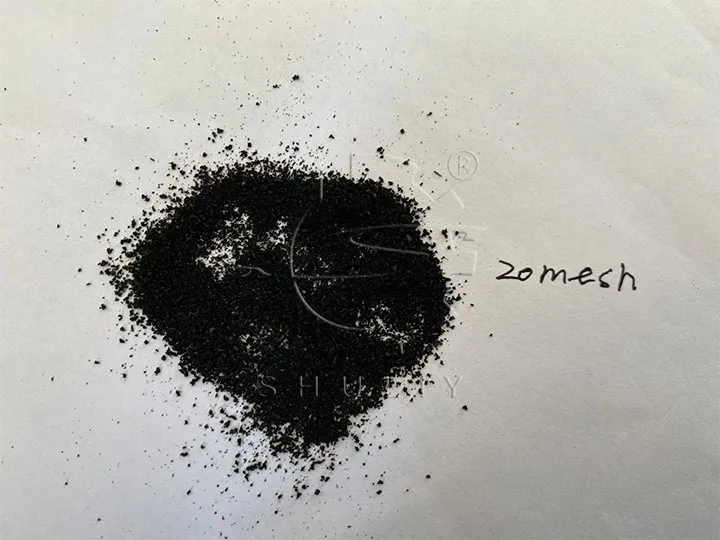

Los neumáticos usados contienen una cantidad significativa de fibra de nailon o poliéster en sus capas de recubrimiento, además de caucho y acero. Durante los procesos de triturado y molienda, estas fibras se descomponen en materiales finos y esponjosos que se mezclan con el polvo de caucho.

- Compromete la calidad del producto: Si no se eliminan, estas impurezas de fibra pueden afectar gravemente el rendimiento de los productos aguas abajo, reduciendo la resistencia, durabilidad y calidad estética de los cauchos terminados.

- Límites de aplicaciones del mercado: Muchas aplicaciones de alto valor, como asfalto modificado y productos moldeados de precisión, tienen requisitos de pureza estrictos para el polvo de caucho. El material que contiene fibra no cumple con estos estándares del mercado.

Nuestra separación de fibras de nailon es la solución profesional diseñada para resolver este desafío industrial crítico.

Principio de Funcionamiento del Separador de Fibras

Nuestro separador de fibras utiliza un principio de clasificación de aire avanzado en un proceso totalmente automatizado y eficiente:

- Alimentación: la mezcla de polvo de caucho, que contiene impurezas de fibras del molino cracker, se transporta a través de un sistema neumático cerrado hacia la cámara principal del separador.

- Clasificación de aire: dentro de la cámara se genera un ciclón de aire controlado con precisión. Debido a que las partículas de caucho son más densas y pesadas, caen por gravedad y se descargan por la abertura en la parte inferior de la unidad.

- Extracción de fibras: simultáneamente, los contaminantes de fibras ligeras y de baja densidad son transportados hacia arriba por la corriente de aire y extraídos de la cámara a través de un conducto separado.

- Recolección: el polvo de caucho purificado y las fibras separadas se dirigen a sus respectivos sistemas de recolección (como un colector ciclón o filtro de campana), logrando una separación limpia y completa de los dos materiales.

Este proceso no solo es altamente eficiente (típicamente más del 99%), sino que también opera dentro de un sistema de presión negativa completamente cerrado, que controla eficazmente el polvo y mantiene un ambiente de taller limpio.

Ventajas y Características Clave

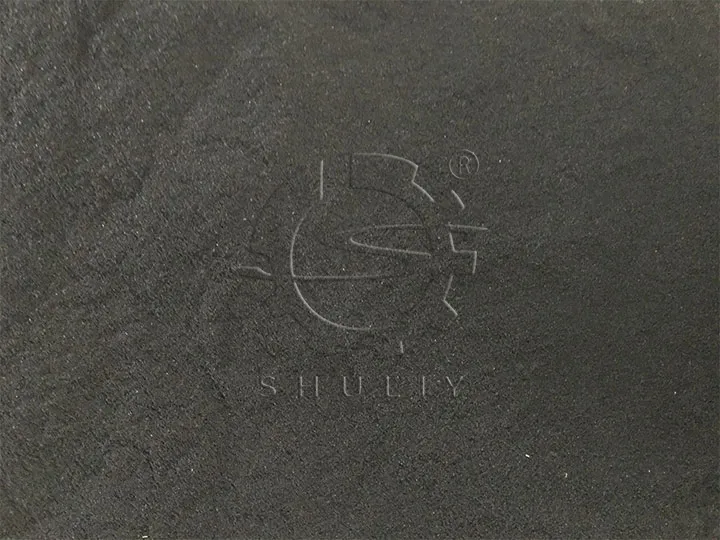

- Eficiencia de separación superior: Diseñado específicamente para las diferentes propiedades físicas del caucho y la fibra, nuestra máquina elimina la gran mayoría de las fibras finas, mej○rando significativamente la pureza del polvo de caucho.

- Integración sin fisuras: Con una huella compacta, la unidad puede integrarse fácilmente en instalaciones nuevas o existentes líneas de producción de polvo de caucho, conectando perfectamente con molinos de cribado y sistemas de envasado aguas abajo.

- Operación confiable con mantenimiento fácil: La máquina no contiene piezas complejas y propensas a desgaste, asegurando un rendimiento estable con requisitos de mantenimiento diario mínimos, lo que garantiza una producción continua.

- Aumenta el valor del producto final: Producir un polvo de caucho más puro te permite acceder a mercados más exigentes, dándote una ventaja competitiva más sólida y márgenes de beneficio más altos.

Posición en la Línea de Producción de Polvo de Caucho

El separador de fibras actúa como el “punto de control de calidad” para el producto final. En una planta completa de reciclaje de neumáticos, su posición estándar es:

Trituradora de Neumáticos → Molino Rompe Caucho → Separador de Fibras → Sistema Final de Envasado

Este diseño de proceso garantiza que todos los contaminantes principales (acero y fibra) hayan sido eliminados efectivamente antes de que el producto final sea envasado.

Parámetros Técnicos de la Máquina Separadora de Fibras

| Artículo | parámetro técnico |

| Potencia del motor | 5.5 KW |

| Velocidad del motor | 760 r/min |

| Capacidad | 800-1000 kg/h |

| Largo*Ancho*Alto | 1500*1500*3400 mm |

| Peso | 1600 kg |

Contáctenos para Mejorar la Pureza de Su Producto

Como fabricante profesional de maquinaria de reciclaje de neumáticos, no solo ofrecemos máquinas individuales de alto rendimiento, sino también soluciones completas y automatizadas de reciclaje de neumáticos.

Si busca mejorar la calidad de su línea existente de polvo de caucho o está planificando construir una nueva línea capaz de producir polvo de caucho de alta pureza, contacte a nuestros expertos técnicos hoy. Le proporcionaremos una consulta técnica detallada y un plan de configuración de equipos óptimo.