Eine Hochleistungs-Gummipulvermühle steht im Mittelpunkt der vollständigen Reifenrecyclinglösung Shuliy Machinery, die kürzlich an einen Kunden in Kanada geliefert wurde. Der Kunde wollte ein lokales Geschäft aufbauen, um Abfallreifen in langlebige Gummibodenfliesen umzuwandeln, um Ressourcen zu recyceln und einen kommerziellen Wert zu erzielen. Shuliy Machinery bot ihm eine End-to-End-Lösung, von der Reifenzerlegung und Pulverherstellung bis hin zur Endplattenformung.

Bedürfnisse und Herausforderungen des Kunden

Die primäre Herausforderung für unseren kanadischen Kunden bestand darin, Abfallreifen verschiedener Größen zu verarbeiten, mit einem maximalen Durchmesser von 1200 mm. Sein ultimatives Ziel war es, hochwertige Gummiplatten in verschiedenen Spezifikationen herzustellen, um lokale Märkte wie Spielplätze, Fitnessstudios und Gehwege zu beliefern. Daher benötigte er eine vollständige und integrierte Produktionslinie, die jeden Schritt nahtlos vom Rohmaterial bis zum Fertigprodukt bewältigen kann.

Die kundenspezifische Lösung: Vom Reifen zum Pulver

Basierend auf den Rohstoffen und Produktionszielen des Kunden haben wir eine komplette und effiziente Gummipulverproduktionslinie konfiguriert.

Schritt 1: Reifenvorbehandlung

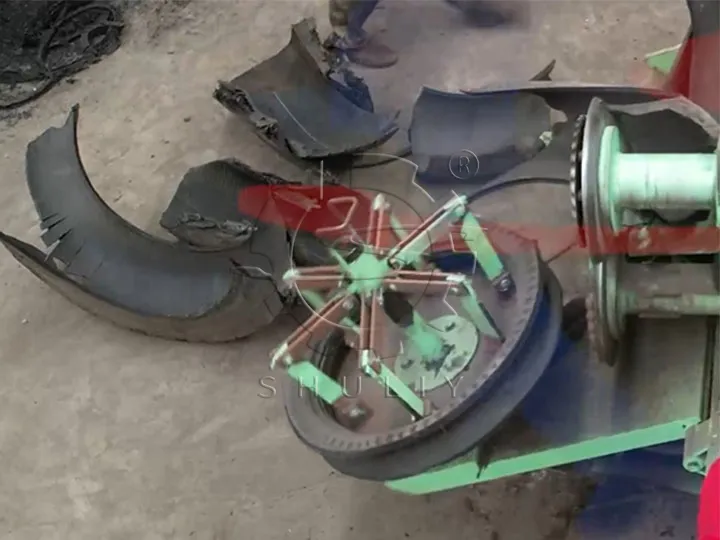

Zuerst haben wir die Produktionslinie mit einerReifenzerlegemaschineausgestattet. Diese Maschine entfernt mühelos die Stahlfederkantenringe von beiden Seiten der 1200 mm Reifen und schneidet den verbleibenden Teil in Abschnitte. Dies bereitet das Material für den nachfolgenden Zerkleinerungsprozess vor und verbessert die Verarbeitungseffizienz der gesamten Reifenrecyclinglinie erheblich.

Zusätzlich ist die Produktionslinie mit einem speziellenReifenbeaddrahtseparatorausgestattet. Diese Maschine verarbeitet die aus den Reifen geschnittenen Kantenringe und trennt effizient den inneren Stahlfaden vom Gummi. Währenddessen wird der Hauptreifen, bei dem die Kanten entfernt wurden, direkt an den Zerkleinerer für die nächste Zerkleinerungsstufe geschickt.

Schritt 2: Grobzerkleinerung

Die zugeschnittenen Reifenstreifen werden in einen 800Reifenzerkleinerereingespeist, der sie schnell in 3-8 cm große Gummistücke zerreißt.

Schritt 3: Feinmahlung mit der SL-400 Gummipulvermühle

Diese Gummiknollen werden dann zum Kern des Systems transportiert: die SL-400Gummipulvermühle. Diese leistungsstarke Gummizerkleinerungsmaschine zerkleinert die Knoten in die erforderliche Maschenweite, während die integrierten magnetischen und fasertrennenden Systeme der Linie automatisch Stahlfäden und Nylon entfernen, um die Reinheit des endgültigen Gummipulvers zu gewährleisten. Die stabile Leistung unserer Gummipulvermühle war ein entscheidender Faktor für die Entscheidung des Kunden.

Vom Pulver zum Produkt: Herstellung hochwertiger Gummifliesen

Das hochwertige Pulver, das von der Gummipulvermühle hergestellt wird, ist das ideale Rohmaterial für die Herstellung von Fliesen. Dieses Pulver wird in einem 250-Mischer mit einem Bindemittel und anderen Additiven vermischt und anschließend in Formen gegossen. Schließlich wird das Material durch die Hochtemperatur- und Druckformmaschine vulkanisiert, um starke und langlebige Gummifliesen zu erhalten.

Um den vielfältigen Marktanforderungen des Kunden gerecht zu werden, haben wir Formen für die Herstellung von Fliesen in den Maßen 500x500 mm und 1000x1000 mm in verschiedenen Mustern geliefert.

Eine erfolgreiche Partnerschaft & Ihr nächstes Projekt

Dieses Projekt zeigt deutlich, wie eine gut gestaltete Recyclinglinie Abfall in ein profitables Geschäft verwandeln kann. Der kanadische Kunde ist jetzt vollständig ausgestattet, um hochwertige Gummifliesen in seinem lokalen Markt zu produzieren und zu verkaufen.

Wenn Sie auch in ein Reifenrecyclingprojekt investieren möchten, egal ob Sie eine eigenständige Gummipulvermühle oder eine komplette schlüsselfertige Lösung benötigen, steht Ihnen unser professionelles Team gerne zur Verfügung. Kontaktieren Sie uns noch heute für eine individuelle Beratung.