Laini ya kuosha chupa ya PET ya Shuliy Machinery ni suluhisho kamili la kuchakata chupa za PET. Kupitia safu ya vifaa vya hali ya juu vya kupasua, kufua na kukaushia, chupa za PET hatimaye huchakatwa kuwa flakes za PET zisizo na uchafuzi. Laini yetu ya kawaida ya kuchakata chupa za PET ina uwezo wa 500kg/h-6000kg/h, na tunaweza kubinafsisha usanidi wa vifaa vya laini na uwezo kulingana na mahitaji yako.

Ikiwa unataka kuanzisha biashara ya kuchakata chupa za PET, kuwekeza kwenye mashine ya kuchakata chupa za PET ni chaguo nzuri, kiwanda chetu cha kuchakata chupa za PET kimesafirishwa hadi Nigeria, Msumbiji, Kongo, Saudi Arabia na nchi nyinginezo.

Utangulizi wa Mstari wa Usafishaji wa Chupa za PET

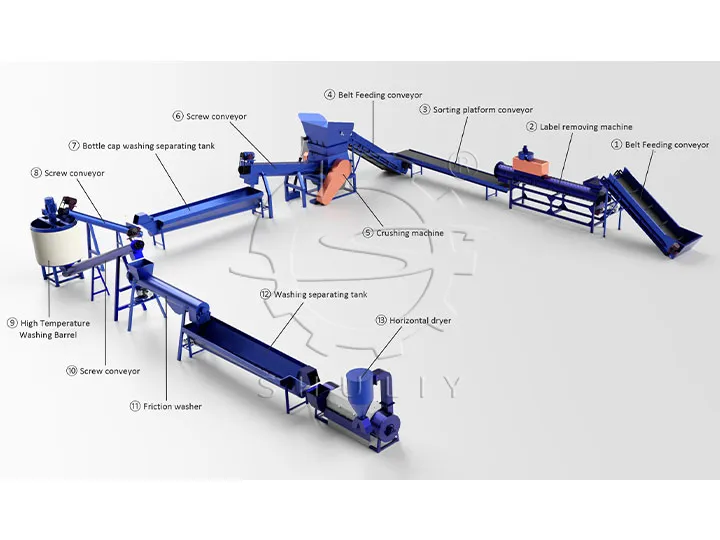

Kifaa kikuu cha kiwanda hiki cha usafishaji wa chupa za PET kinajumuisha kifaa cha kuondoa lebo za chupa za PET, mashine ya kusaga chupa za plastiki, tangi la kuelea la plastiki, tangi la kuoshea moto, mashine ya kusafisha msuguano wa plastiki, na kiunika mlalo. Ili kuhakikisha ubora wa vipande vya PET vya mwisho, unachagua hatua nyingi za kuosha.

Laini hii ya kuosha chupa za PET hutumiwa sana kuosha na kuchakata tena chupa za plastiki zilizotengenezwa na PET kama vile chupa za maji ya madini, chupa za vinywaji, chupa za maziwa, na kadhalika. Vifuniko hivi vya chupa vinaweza kutumika zaidi kwa ajili ya uzazi au pelletizing, ambayo hutumiwa sana katika sekta ya utengenezaji wa plastiki. Mashine zetu za chakavu za chupa za plastiki zinafaa kwa makampuni ya biashara ya ukubwa wote na zinaweza kubinafsishwa kulingana na mahitaji maalum ya wateja ili kuhakikisha uendeshaji bora na pato la ubora wa mstari wa uzalishaji.

Manufaa ya Mashine ya Kusafisha Chupa ya PET

- Uwezo wa ubora wa juu wa kusafisha: Hakikisha kuwa uchafu wa uso na wa ndani wa chupa za PET umeondolewa kikamilifu ili kuimarisha ubora wa flakes za chupa zilizorejeshwa.

- Usanidi unaobadilika: Laini ya kuosha chupa ya PET inaweza kubinafsishwa kulingana na mahitaji maalum ya mteja, kiwango cha uzalishaji, na mpangilio wa mmea ili kutoa suluhisho bora.

- Mahitaji ya ubora: Hakikisha kuwa ukavu, thamani ya pH, mnato bainifu, maudhui ya PVC, n.k. ya vifuniko vya mwisho vya chupa za PET zinazozalishwa vinakidhi viwango.

Malighafi na Bidhaa za Mwisho za Laini ya Kuosha Chupa za PET

Malighafi ya mitambo ya kuchakata chupa za PET ni kila aina ya taka za chupa za PET, kama vile chupa za maji ya madini, chupa za vinywaji, chupa za juisi, chupa za maziwa, chupa za bia, nk. Bidhaa ya mwisho ni chupa za PET zilizosindikwa.

Ubora wa flakes za chupa za PET zilizorejeshwa zinaweza kuainishwa kulingana na rangi, kutoka juu hadi chini, kama flakes nyeupe safi, flakes ya samawati isiyokolea, flakes za kijani kibichi, flakes za manjano, na flakes zingine. Kwa watayarishaji wa kuchakata tena, vifurushi vya ubora wa juu baada ya uainishaji na usafishaji vikali vinaweza kukidhi mahitaji ya soko la hali ya juu na kuongeza thamani ya bidhaa.

Jifunze zaidi: Mambo Yanayoathiri Mabadiliko ya Bei ya Usafishaji wa Vipande vya Chupa za PET Zilizosafishwa

Video ya Kazi ya Kiwanda cha Usafishaji cha Chupa ya PET

Hatua za Usafishaji wa Mstari wa Kuosha wa Flakes za PET

Mtiririko wa kazi wa laini ya kuosha PET flakes kawaida hujumuisha hatua zifuatazo muhimu.

- Kukusanya chupa za PET: Kwanza, kusanya chupa za PET zilizotupwa kutoka vyanzo tofauti kama vile vituo vya kuchakata, maduka makubwa, mikahawa na kaya.

- Upakiaji: Chupa za plastiki zinazokusanywa kutoka kwenye majalala ya takataka kwa kawaida huhitaji kupakuliwa kwanza.

- Kusagwa: Chupa za PET zilizopangwa hutiwa ndani ya mashine ya kukata chupa za plastiki ili kuzikatwa kuwa flakes ili kupunguza ukubwa wao.

- Kusafisha: Kuosha chip za chupa za PET ili kuondoa uchafu wa uso, grisi, na kuweka lebo. Hii inaweza kujumuisha hatua nyingi za kuosha ili kuhakikisha kuwa vipande vya chupa vinakuwa safi.

- Kukausha: Kukausha pellets za PET zilizooshwa ili kuondoa unyevu wowote uliobaki na kuhakikisha kuwa zinakidhi viwango vya ubora.

Video ya 3D ya Laini ya Kuosha Chupa za PET

Video inaonyesha mchakato wa kuchakata chupa za PET wa 1000kg/h. Mashine zetu za kuchakata chupa za PET zinapatikana katika matokeo mbalimbali ili kukidhi mahitaji ya wasafishaji wengi.

Mashine Kuu ya Kusafisha Chupa ya PET

Kiondoa lebo za chupa za PET: Hatua ya kwanza ya laini ya usafishaji wa chupa za PET kwa kawaida huondoa lebo za PVC. Kiondoa lebo za chupa za PET huondoa lebo kwa ufanisi, kiwango cha kuondoa lebo ni hadi 98%, na kiwango cha juu cha otomatiki, badala ya kuondoa lebo kwa mikono.

Mashine ya kusaga chupa za plastiki: Mashine hutumiwa kusaga chupa za plastiki kuwa vipande vya chupa kwa ajili ya kuosha na kusafisha baadaye. Nyenzo ya blade ya mashine ya kusaga chupa za plastiki ni 9Crsi kwa maisha marefu.

Tangi la kuelea la plastiki: Kifaa hiki hutumiwa kutenganisha vipande vya chupa za PET kutoka kwa kofia au lebo. Inapotumiwa vipande vya chupa za PET vitazama na kusafirishwa hadi hatua inayofuata kupitia skrubu chini, wakati lebo au kofia zitafuka juu ya uso wa maji.

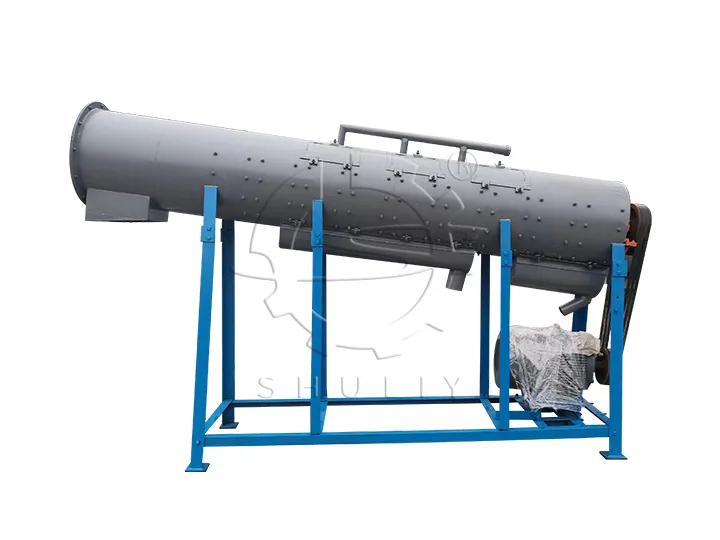

Tangi la kuoshea moto: Matangi ya kuosha moto husafisha vipande vya chupa za PET kupitia maji ya joto la juu na sabuni za kemikali. Ni bora zaidi kuliko kuosha baridi, inaweza kuondoa kwa ufanisi uwepo au kutokuwepo pamoja na gundi iliyobaki, n.k.

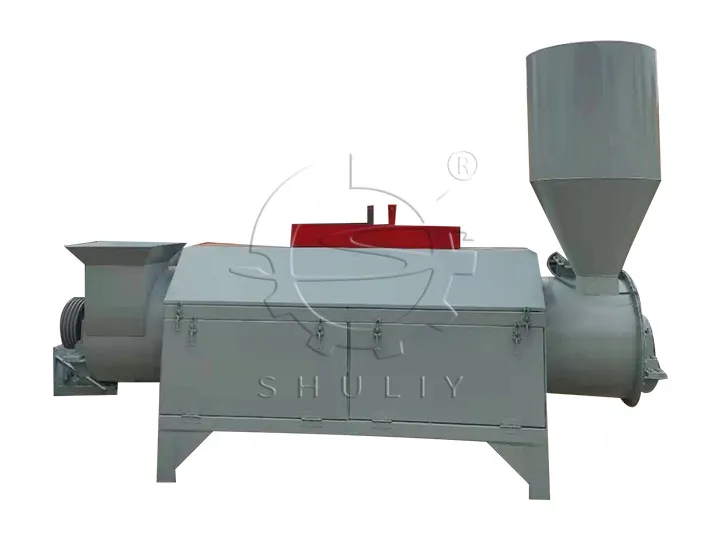

Mashine ya kusafisha msuguano wa plastiki: Ndani ya mashine, kuna sahani nyingi za kusugua na kamba za kusugua ili kuosha sabuni iliyoletwa kutoka kwenye tangi la kuosha moto na kupunguza kiwango cha pH.

Kiunika mlalo: Mashine inaweza kuondoa 98% ya maji katika vipande vya chupa za PET, na kwa bomba la kukausha nyuma, maji yanaweza kudhibitiwa kwa 0.5-1%.

1000kg/h Vigezo vya Mstari wa Usafishaji wa Chupa ya PET

Ifuatayo ni maelezo kuhusu vigezo vya baadhi ya mashine za kiwanda cha kuchakata chupa za PET, pia tunayo miundo mingi na matokeo mbalimbali ya mashine. Ikiwa unahitaji, tafadhali acha maelezo yako katika fomu kwenye tovuti yetu, na tutakutumia maelezo ya mashine mara moja.

| Kipengee | Vipimo | Qty |

| Kiondoa lebo ya chupa za PET | Voltage: 380V, 50HZ, awamu ya 3 ya umeme Nguvu: 15+3+1.5kw Urefu wa pipa: 4.3m, kipenyo: 0.63m Kiwango cha chupa kisicho na lebo 98% Maudhui ya PVC/(mg/kg) ≤ 100-300 (mg/kg) | 1 |

| Mashine ya kukamulia chupa za plastiki | Voltage: 380V, 50HZ, awamu ya 3 ya umeme Nguvu: 37+1.5KW+1.5kw Zana: 9Crsi Uzalishaji: 1000KG/H Ukubwa wa skrini: 18mm Unene wa sahani ya kisu: 40mm | 1 |

| Tangi ya kuelea ya plastiki | Voltage: 380V, 50HZ, awamu ya 3 ya umeme Nguvu: 3KW Unene wa ukuta wa nje: 4 mm Unene wa blade: 6 mm Ukubwa wa vifaa: 5000 * 1000 * 1000mm | 3 |

| Tangi ya kuosha moto | Voltage: 380V, 50HZ, awamu ya 3 ya umeme Motor 4kw Nguvu ya joto ya sumakuumeme: 80KW Urefu: 2000mm, kipenyo: 1300mm | 2 |

| Mashine ya kuosha ya msuguano | Voltage: 380V, 50HZ, awamu ya 3 ya umeme Nguvu: 7.5KW Urefu wa pipa: 3000mm, kipenyo: 400mm Unene wa blade: 6 mm | 2 |

| Mashine ya kuondoa maji ya plastiki | Voltage: 380V, 50HZ, awamu ya 3 ya umeme Nguvu: 15KW Ondoa unyevu na kufikia kiwango cha kukausha cha karibu 95-98% | 1 |

| Kukausha mabomba | Voltage: 380V, 50HZ, umeme wa awamu ya 3 Kipenyo 159mm, urefu 15m Nguvu ya kupokanzwa 30kw, inapokanzwa na unyevu 0.5% Motor 7.5+3kw Nyenzo ya mawasiliano sehemu 304 chuma cha pua Unyevu(%)≤0.5-1% | 1 |

| Kitenganishi cha upepo | Voltage: 380V, 50HZ, umeme wa awamu 3 Kipenyo 0.8m, urefu 4.5m; Motor 2.2kw3 shabiki msaidizi: 0.753 Elevator motor 3kw Kwa kuondoa alama ya biashara iliyobaki na vumbi Maudhui ya uchafu/(mg/kg)≤300-500 Maudhui ya unga/(mg/kg)≤2000-3000 | 1 |

Juu ni vigezo vya kina vya vifaa kuu vya mstari wa kuosha chupa za PET 1000kg / h. Miongoni mwao, duct ya kukausha na kitenganishi cha hewa yanafaa kwa matukio yenye pato kubwa na mahitaji ya ubora wa flakes ya chupa za PET.

Mstari wa Kuosha Chupa za PET Kesi Zilizofanikiwa

Mashine Iliyobinafsishwa ya Kuchakata Plastiki ya PET Imesafirishwa Hadi Naijeria

Mashine yetu maalum ya kuchakata plastiki ya PET imesafirishwa kwa ufanisi hadi Nigeria na tutaendelea kufuatilia utendakazi wa mashine katika kiwanda cha Nigeria.

Kwa maelezo zaidi, tafadhali angalia: Laini ya Kuosha Vipande vya Chupa za PET Imepelekwa Nigeria

Laini ya Kuosha Matambara ya PET Imetumwa Kongo

Mteja kutoka Kongo amenunua laini kamili ya kuosha PET flakes kutoka Shuliy Machinery, ambayo sasa inafanya kazi hapa nchini.

Kwa maelezo zaidi, tafadhali angalia: Kiwanda cha Kuosha Chupa za PET Kilipelekwa Kongo

Kiwanda cha Kusafisha Chupa cha PET Kusafirishwa hadi Msumbiji

Hapo awali, mteja kutoka Msumbiji alibinafsisha kiwanda cha kuchakata chupa za PET kwenye Shuliy Machinery, hii hapa ni video ya uwasilishaji.

Kwa maelezo zaidi, tafadhali angalia: Laini ya Usafishaji wa Chupa za PET Imepelekwa Msumbiji

Mtengenezaji Bora wa Laini ya Kuosha Chupa za PET

Je, unatafuta mtengenezaji bora wa laini ya kuosha chupa za PET? Tumejitolea kutoa wasambazaji wa mashine za kuchakata chupa za kipenzi za ubora wa juu ili kukidhi mahitaji yako. Bidhaa zetu zinakidhi viwango vya tasnia na hutoa masuluhisho ya kuaminika ya kuchakata tena chupa za plastiki. Ikiwa unatafuta mtengenezaji anayeaminika, tutafurahi kukupa huduma za kitaaluma.