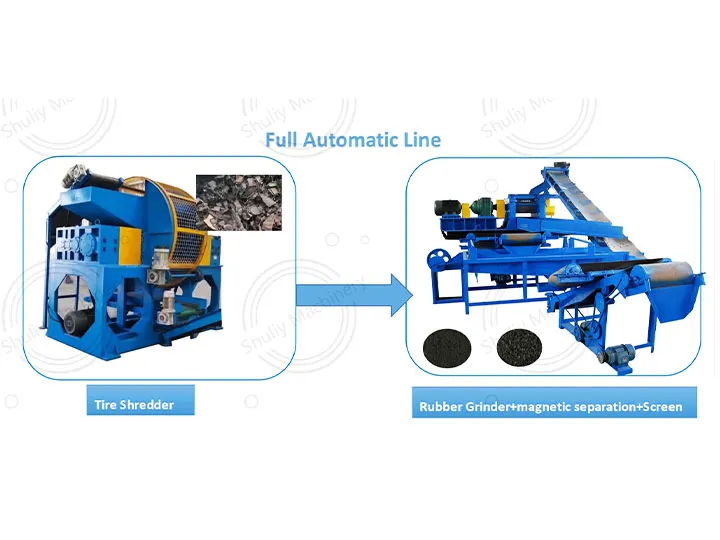

我们的全自动废物轮胎回收线是一种先进的解决方案,旨在将废物轮胎处理成干净,高质量的橡胶颗粒或橡皮粉,并使用最少的手动干预。该系统从切碎,磨碎,筛选,磁分离,纤维分离到最终材料收集,实现了完全自动化。

原料

我们的全自动轮胎回收线专门设计用于处理直径小于1200mm的所有类型的废轮胎,包括汽车轮胎,卡车轮胎和轻型工程轮胎。对于较大的轮胎,例如OTR轮胎,我们还提供相应的解决方案。

成品

通过全自动废轮胎回收线处理后,可以获得以下成品:

- 橡胶颗粒(1-5mm):用于跑道,草坪填充和橡胶产品制造。

- 橡胶粉(10-40网格):用于再生橡胶生产和橡胶产品加工。

- 钢丝:通过磁分离恢复,用作冶炼或后处理的原材料。

- 纤维杂质:通过空气分离分开,方便用于集中治疗或回收利用。

成品橡胶颗粒或粉末的纯度可以高达99%,从而确保了随后应用的质量和稳定性。

废轮胎回收线的主要特征

- 轮胎尺寸处理:专门针对直径的轮胎设计 小于1200mm,包括汽车轮胎,卡车轮胎和轻型OTR轮胎。

- 最终产品:生产 1-5mm橡胶颗粒或10-40网地橡胶粉,适用于广泛的应用。

- 灵活的容量:能够处理每天几吨到数十吨的生产要求,满足大小回收操作的需求。

- 完全自动化的过程:通过智能输送,存储和物料分离系统降低人工成本并提高生产效率。

可用的三种预处理解决方案

为了满足不同的客户需求和物质条件,我们在精细橡胶研磨阶段之前提供三种预处理选项:

1,轮胎辩论者 +轮胎切割机 +切碎器线

- 轮胎去钢圈机:去除轮胎钢圈中的钢丝。

- 轮胎切割机:将轮胎切割成更小的部分。

- 轮胎粉碎机:将轮胎切块粉碎成橡胶块。

- 中间输送机:自动转移材料。

- 橡胶块存储系统:存储粉碎后的橡胶块。

- 自动卸料输送机:将材料送入橡胶粉机。

- 橡胶破碎机:将块状物研磨成颗粒或粉末。

- 纤维分离器:分离尼龙纤维。

- 橡胶收集系统:收集并转移最终产品。

2,集成式钢圈切割机和轮胎切割机 + 钢丝分离器 + 轮胎粉碎机生产线

- 珠切割和轮胎切割机:集成轮胎珠和轮胎部分的切割。

- 钢丝分离器:高效分离嵌入的钢丝。

- 破碎机及后续系统与解决方案1相同。

3,直接粉碎线

- 轮胎破碎机:将轮胎直接撕碎成小块。适用于已预切或去除珠的轮胎。

- 随后是中间输送机、存储系统、卸料输送机、橡胶破碎机、纤维分离器和收集系统,和其他解决方案一样。

为什么选择我们的全自动废旧轮胎回收生产线?

- 高自动化:最小化人工劳动,最大化产出稳定性。

- 模块化设计:易于根据特定原材料和最终产品要求进行定制。

- 高效分离:高纯度橡胶颗粒和粉末,钢丝和纤维含量降至最低水平。

- 可靠性能:采用耐用组件,适合长期连续运行。