废旧塑料造粒生产线是将废旧塑料转化为可再利用颗粒的关键工业流程。该生产线的工作流程既复杂又至关重要,直接影响回收塑料的质量和可用性。本文将深入探讨塑料颗粒挤出生产线的工艺,揭示每个关键步骤的重要性。

废塑料造粒线工作流程

第1步:原材料收集

该过程从收集原材料开始,包括各种塑料,包括薄膜或硬质塑料。这些废弃材料是废塑料造粒线后续阶段的基础。

第二步:撕成小碎片

收集到的塑料,无论是薄膜还是硬质塑料,都将通过塑料破碎机回收机进行粉碎。这一关键步骤将塑料减小为更小、更易于处理的碎片,从而提高整个工艺的效率。

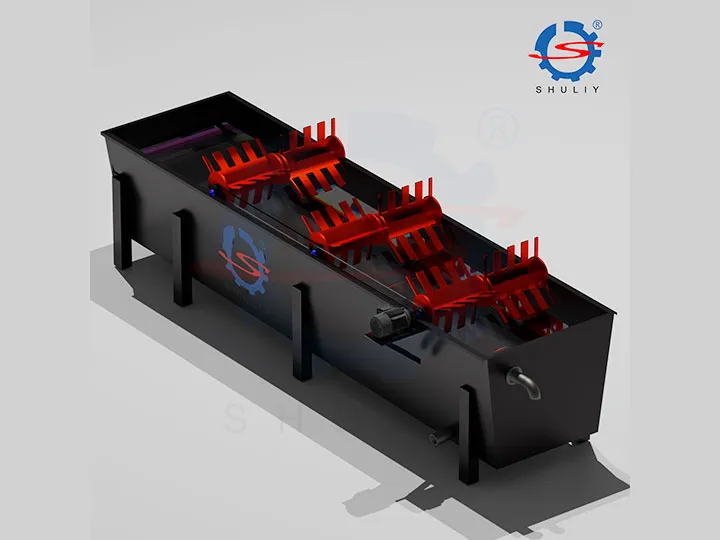

第三步:清洗和干燥

粉碎过程结束后,塑料碎片进入塑料清洗罐。在这里,进行彻底的清洗操作以去除杂质,确保塑料在原始状态下为进一步加工做好准备。清洗后的物料进入塑料脱水机去除水分,确保塑料干燥并适合造粒。

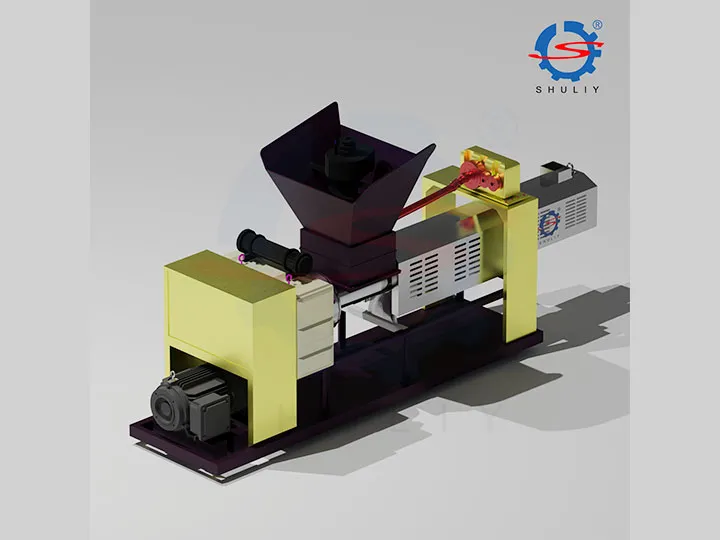

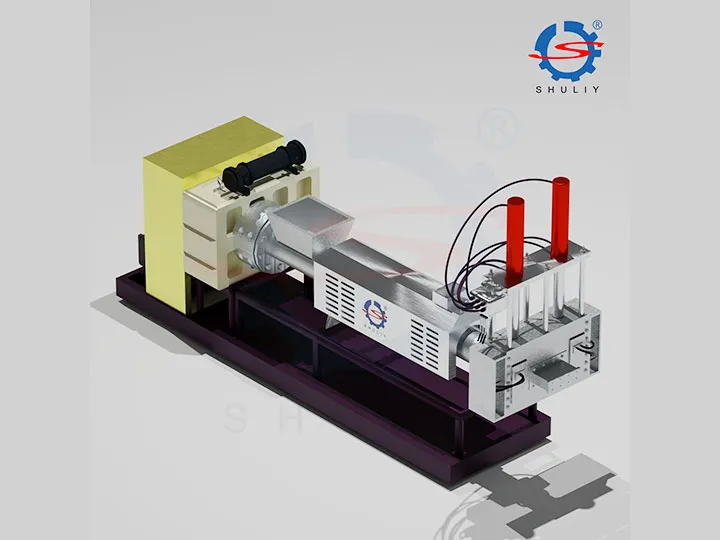

第四步:熔化和挤压

清洁后的塑料碎片进入废旧塑料颗粒制造机,在那里被熔化并挤出成长的塑料条。这是从废料到可再利用材料的关键中间步骤。

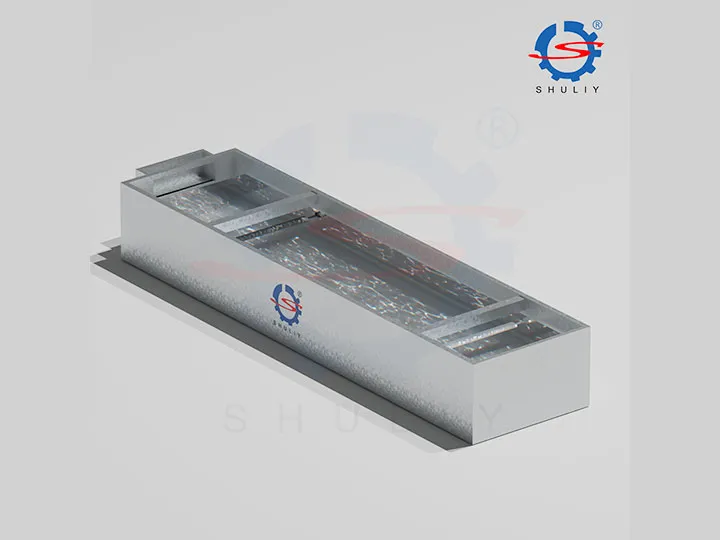

第5步:冷却和切割

挤出的塑料条进入冷却槽,在那里经历关键的冷却和固化过程。此步骤确保塑料条固化成稳定的形式,为后续造粒奠定基础。然后,固化的塑料段被输送到塑料颗粒切割机,在那里它们被精确切割以形成尺寸均匀的颗粒。这种造粒工艺对于生产适合各种应用的高质量塑料颗粒至关重要。

第6步:包装和储存

废塑料造粒线的最后阶段涉及对生产的颗粒进行包装。包装后,颗粒储存在适当的条件下,等待运送到制造业等各个行业以供再利用。

结论

废塑料造粒生产线的工作流程构成了一个协调而复杂的系统,涉及多个关键步骤,每个步骤都深刻影响最终产品的质量。通过了解和优化每个阶段,制造商可以生产高质量、可重复使用的塑料颗粒。