钢筋矫直机是加工弯曲或废旧钢筋的必备设备,广泛应用于钢铁回收厂和建筑材料准备中。我们公司提供完整的钢筋矫直解决方案,包括适用于6-25毫米钢筋的多型号设备、定制进料口、耐用辊筒和强大的双电机系统,以确保稳定高效的矫直性能。我们还提供型号选择指导、工厂测试、备件供应和海外技术支持,帮助客户快速投入使用。

钢筋矫直机的主要特点

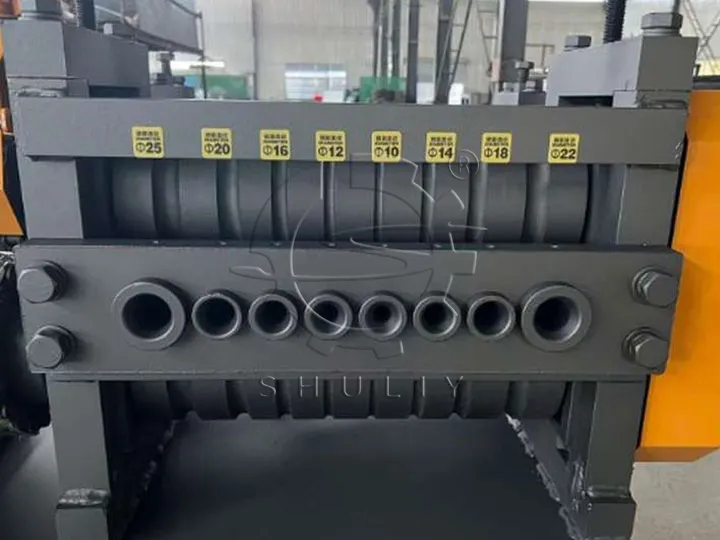

多孔进料设计,适用于不同直径

每款型号都配备多个进料孔,操作员只需选择与钢筋直径匹配的孔位,便于顺畅进料。

除了圆孔外,还提供T型进料口,便于更快更轻松的进料。

耐用加厚矫直辊筒

本机采用加厚耐磨辊筒,延长使用寿命,降低更换成本。

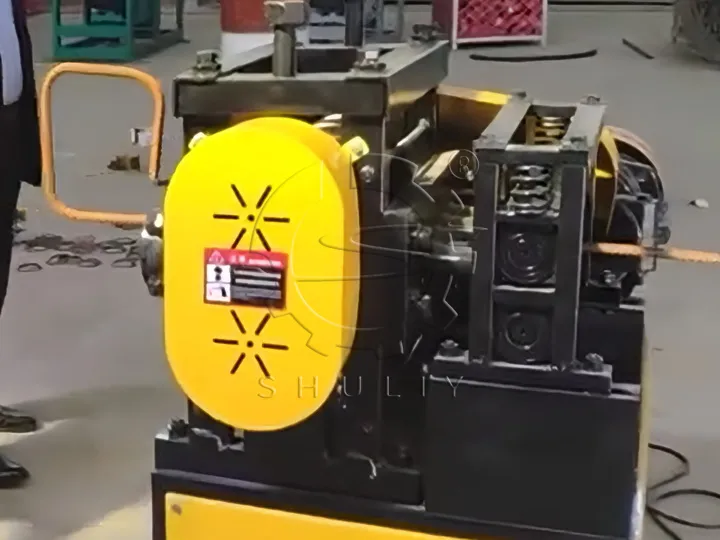

稳定高效的双电机驱动

双电机配置提供强大的矫直力,确保连续稳定运行。

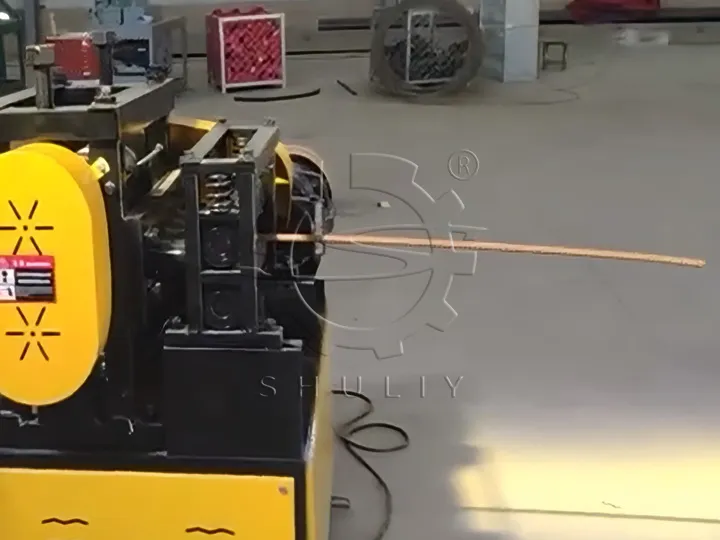

钢筋矫直机的工作原理

钢筋矫直机通过多组矫直辊驱动,利用双电机和减速机系统工作。当钢筋通过选定的进料孔时,辊筒高速旋转,持续施加压力,去除弯曲,恢复钢筋的直线状态。

机器的加厚辊筒确保矫直过程中受力稳定,匹配的进料孔或可选的T型入口帮助不同直径的钢筋顺利引入系统。矫直后,钢筋自动送至出料段进行收集或后续加工。

钢筋校直机型号与规格

| 模型 | 校直杆直径 | 进料孔 | 校直长度 | 电机功率 | 机器重量 | 机器尺寸 |

| 6-10 | 6-10 mm | 5个孔 | 500–2000 mm | 4 千瓦 | 570 kg | 1100×720×1150 mm |

| 6-14 | 6-14 mm | 5个孔 | 500–2000 mm | 5 kW | 730 kg | 1200×789×1220 mm |

| 8-16 | 8-16 mm | 5个孔 | 500–2000 mm | 5 kW | 750 kg | 1250×820×1300 mm |

| 14-25 | 14-25 mm | 6个孔 | 500–2000 mm | 15 千瓦 | 980 kg | 1550×890×1600 mm |

钢筋校直机的应用

- 废钢筋回收

- 施工现场钢筋再利用

- 钢材加工车间

- 废钢筋校直

- 金属回收设施

该钢筋校直机帮助恢复弯曲或废弃的钢筋,提高材料利用率,减少浪费。

为什么选择我们的钢筋校直机?

- 支持广泛的校直范围(6–25 mm)

- 强大的双电机驱动,性能平稳

- 多个进料孔 可选的T型进料口

- 耐用的滚筒,使用寿命长

- 稳定运行,故障率低

请求钢筋校直机报价

如果您需要可靠的钢筋校直机用于加工和回收钢筋,请随时与我们联系。我们的团队将根据您的钢筋直径、产量要求和预算推荐合适的型号。

相关钢筋加工设备

为了支持完整的钢筋加工需求,我们还提供相关的钢筋加工设备。这些包括用于形成圆环的 钢筋环制造机,用于成型建筑箍筋的钢筋箍筋弯曲机,以及用于精确弯曲管道或管子的CNC管道弯曲机。我们的设备满足广泛的加工需求。如需我们的服务,请随时与我们联系。