造粒机的定期保养是保证其正常运转、延长其使用寿命的关键。有效的维护措施不仅可以提高生产效率,还可以降低设备故障率和维护成本。下面介绍一些维护塑料造粒机的有效方法。

定期清洁和润滑

定期清洁造粒机的所有部件是保持其高效运行的基础。及时清除堆积的塑料碎片、灰尘等杂质,确保机器内部保持清洁。同时,定期对机器进行润滑,以最大程度地减少磨损,确保部件平稳运行。

注意零件的磨损和撕裂

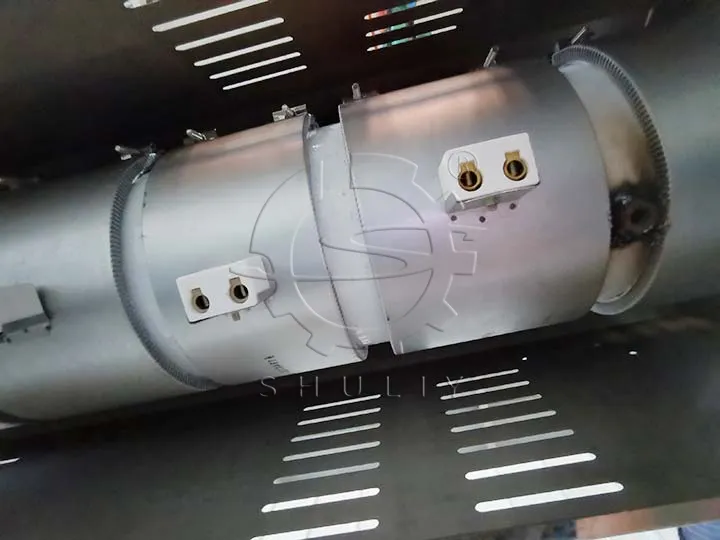

定期检查 plastic pelletizer recycling machine 的关键部件,特别是模头、加热装置和传动系统。当发现有磨损或损坏时应及时更换,以避免部件的磨损影响设备的正常运行。

合理使用和负荷控制

合理使用造粒机是保障其长期运行的关键。避免超负荷作业和长时间连续工作,以防止设备过热和零件损坏。

定期维护记录

创建详细的维护记录,包括何时进行维护、维护什么以及何时更换零件。这有助于跟踪设备的维护情况并及时发现和解决潜在问题。

出售造粒机

通过定期清洁、润滑、零件检查以及合理使用,可以使塑料造粒机回收机保持良好的运行状态,延长其使用寿命。坚持有效的维护措施,不仅可以提高生产效率,还可以降低维护成本。

Shuliy Machinery的granulator machines采用先进的制造工艺,性能可靠。我们提供全方位的售后服务,包括操作说明和维护建议,确保客户能够充分利用设备进行高效的塑料回收加工。