切粒机用于将塑料熔化拉条后切割成塑料颗粒,其刀片是将塑料原料切割成均匀颗粒的关键。它们的设计、材料和操作特性在决定所生产颗粒的质量方面发挥着重要作用。

叶片设计和材料选择

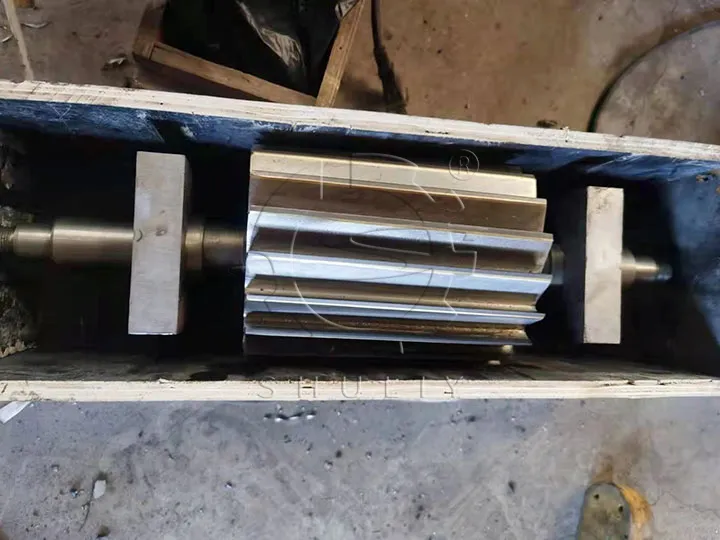

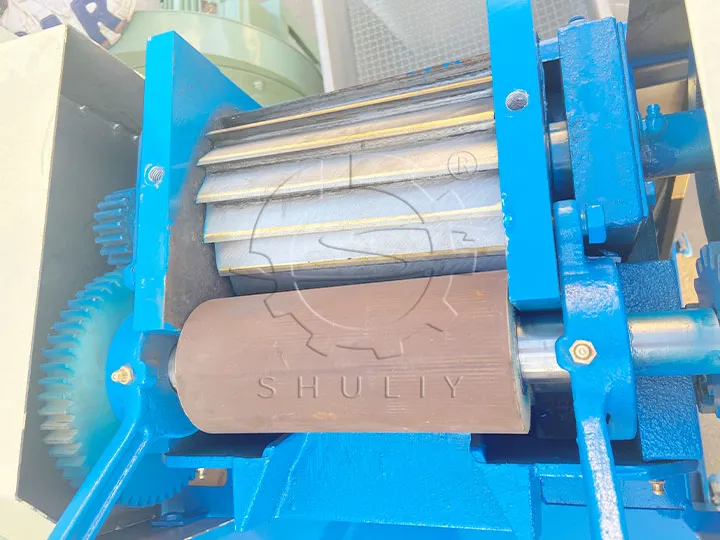

刀片结构在确保高效一致的切割方面起着至关重要的作用。塑料回收机械制造商会仔细构思刀片轮廓,包括形状、尺寸和切割角度,以优化切割过程。刀片材料的选择同样重要。我们的颗粒切割机通常由高质量、耐用的材料制成,例如硬质合金,以承受切割过程中遇到的机械应力和磨损。

颗粒切割机转速

高转速是这些叶片的一个决定性特征。根据待加工塑料的类型、所需颗粒尺寸和切割室配置仔细选择转速。这使得刀片能够快速、干净地切割塑料材料,从而产生精确、均匀的颗粒。

摩擦与润滑

在高速旋转切割过程中,刀片与塑料颗粒之间的摩擦产生热量和磨损,影响切割效率和精度。定期润滑可以有效减少摩擦,减少切割过程中产生的热量,延长刀片的使用寿命,同时保证颗粒切割的质量。

刀片维护和更换

鉴于刀片的高速特性和塑料材料的磨损特性,刀片的维护至关重要。定期检查、磨利和更换磨损的刀片可确保颗粒切割机继续以最高效率运行。