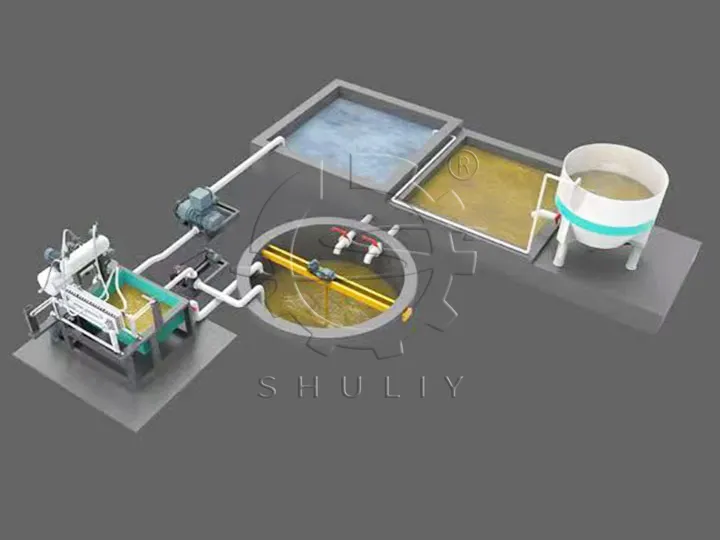

在一个蛋托制造厂,纸浆机系统是整个过程的起点,并在确定产品质量和生产效率方面发挥着关键作用。该系统主要由液压纸浆机、纸浆混合罐、供料泵和振动筛过滤器组成。这些机器协同工作,将废纸加工成均匀、浓度适当的纸浆,确保成型机的稳定供给。

纸浆机的功能

制浆系统是纸浆成型生产线的核心组件。它主要用于分解和混合原材料,如废纸,产生均匀的纸浆,以便于后续的成型过程。

该设备广泛用于生产各种纸浆模制产品,如蛋托、杯架、水果托盘和工业缓冲垫。它在提高产品质量和生产效率方面发挥着关键作用。

广泛适用的原材料

这台纸浆机支持各种类型的废纸材料,包括:

- 旧报纸

- 纸箱纸,书本纸

- 纸屑,纸板等

通过液压搅拌和剪切,原材料迅速被破碎成浆料,无需复杂的预处理。操作简单且高度适应性强。

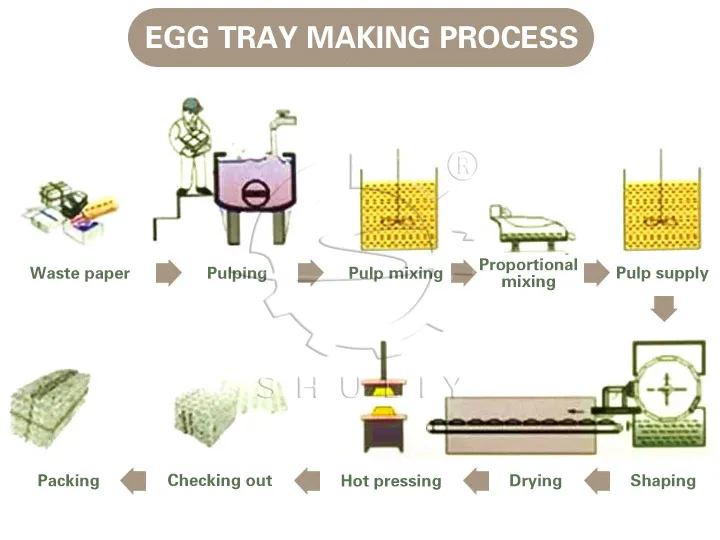

纸浆搅拌机工艺流程

1,液压搅拌机 - 制浆

原材料(如废纸箱、报纸)被送入液压打浆机进行打浆 → 打浆后的浆料流入储存罐以备后用。

2,第一混合罐 + 振动筛过滤

纸浆被泵入混合罐 → 通过振动筛去除杂质 → 搅拌调整纸浆浓度。

3,第二混合罐 - 添加剂混合

纸浆进入第二个罐 → 添加颜料、防水剂等添加剂 → 彻底混合。

4,供浆泵到成型机

准备好的纸浆通过泵送到蛋托成型机进行连续自动生产。

搅拌系统的优点是什么?

- 各种尺寸以满足不同的生产需求,适合小型和大型操作。

- 处理各种类型的废纸,如报纸、纸箱、书籍和纸板。

- 纸浆机的尺寸、电机功率和进料方式可以根据工厂布局和产能需求定制。

- 优化的叶轮确保均匀混合,以实现一致且强劲的纸浆输出。

纸浆机参数

| 模型 | 容量(千克/次) | 体积 (立方米) | 尺寸 (毫米) | 功率(千瓦) |

| SL-1.0 | 300 | 1.2 | 1400 × 1200 × 1400 | 7.5 |

| SL-2.0 | 400 | 2.0 | 1550 × 1500 × 1400 | 11 |

| SL-4.5 | 600 | 4.5 | 2200 × 2200 × 2600 | 12 |

我们根据客户的生产能力和可用的工厂空间推荐最合适的型号。所有纸浆机均可定制——包括功率设置、结构尺寸和进料/排料方式——以确保高效生产和最佳布局。请联系我们以获取量身定制的解决方案。