再生PET瓶片的质量直接影响利润水平,因此提高再生PET瓶片的质量是PET回收行业的重要环节。提高再生PET瓶片质量的关键在于优化PET清洗线的工艺,尤其是在处理湿度、PVC含量和特性粘度方面。

利用 PET 清洗线提高 PET 瓶片质量

湿度管理

水分是影响回收PET瓶片质量的最重要因素之一。水分含量过高会影响产品性能和加工。因此,清洗后应尽量减少PET瓶片的水分含量。

为此,建议使用脱水干燥设备,如PET瓶片干燥机,或者,如果有更高要求,使用干燥管或风选机,将水分含量降至5%以下。

PVC含量控制

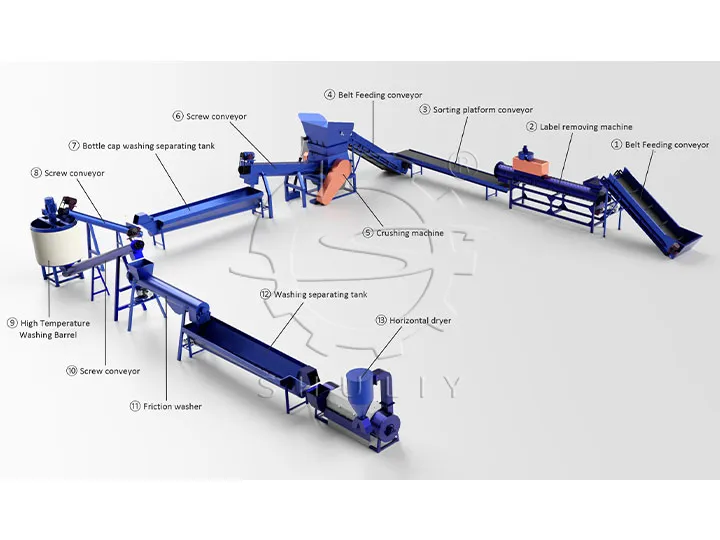

废PET瓶中PVC含量较高,主要以标签纸的形式存在。为了确保回收PET瓶片的质量,在加工前必须将PVC完全去除。这可以通过塑料瓶脱标机来实现,该机的脱标率超过98%。

然后,水槽浮子塑料分离器可以分离残留的 PVC 碎片。另外,在热洗槽中添加清洁粉可以进一步降低PVC含量,保证生产出更高质量的回收PET瓶片。

特性粘度管理

特性粘度是回收PET瓶片的重要指标之一,过度的清洗过程会导致物理性能的改变,特别是粘度的下降。为了避免这种情况的发生,需要在洗涤过程中控制烧碱的用量和洗涤时间,以保证瓶片的特性粘度稳定。通常建议在热洗槽中的处理时间不要超过45分钟,以保持产品的稳定性和一致性。

结论

总之,优化PET清洗线工艺是提高再生PET瓶片质量的关键。通过合理管理湿度,控制PVC含量和特性粘度,我们可以生产出更高质量的再生PET瓶片,提高利润水平,同时为环境保护做出积极贡献。