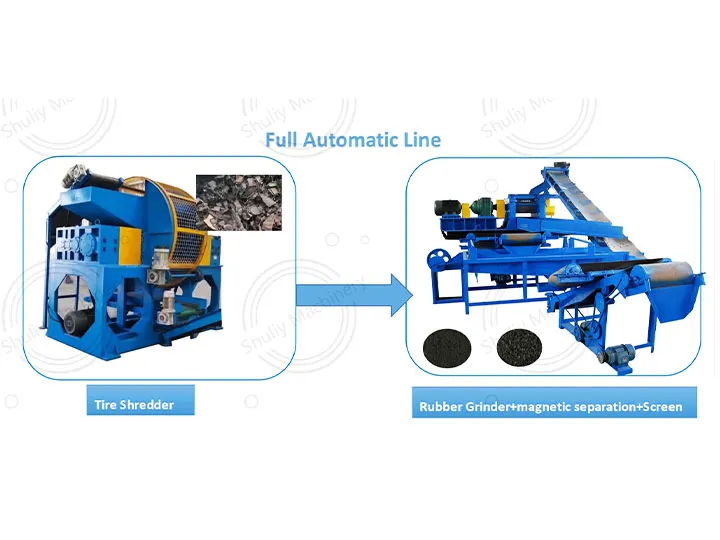

Mstari wetu wa kuchakata taka moja kwa moja wa taka ni suluhisho la hali ya juu iliyoundwa kusindika matairi ya taka ndani ya granules safi, zenye ubora wa juu au poda ya mpira, na uingiliaji mdogo wa mwongozo. Mfumo unafikia automatisering kamili kutoka kwa kugawa, kusaga, uchunguzi, utenganisho wa sumaku, utenganisho wa nyuzi, hadi ukusanyaji wa nyenzo za mwisho.

Malighafi

Mistari yetu ya kuchakata tairi kamili imeundwa mahsusi kusindika kila aina ya matairi ya chakavu na kipenyo cha chini ya 1200mm, pamoja na matairi ya gari, matairi ya lori na matairi ya uhandisi nyepesi. Kwa matairi makubwa, kama matairi ya OTR, tunatoa pia suluhisho zinazolingana.

Bidhaa iliyomalizika

Baada ya kusindika na laini ya kuchakata taka moja kwa moja, bidhaa zifuatazo za kumaliza zinaweza kupatikana:

- Granules za mpira (1-5mm): Inatumika kwa barabara ya kukimbia, kujaza lawn, na utengenezaji wa bidhaa za mpira.

- Poda ya Mpira (Mesh 10-40): Kwa uzalishaji wa mpira uliosindika na usindikaji wa bidhaa za mpira.

- Waya wa chuma: Inapatikana kwa kujitenga kwa sumaku, inayotumika kama malighafi kwa kuyeyuka au kubatilisha tena.

- Uchafu wa nyuzi: kutengwa na utenganisho wa hewa, rahisi kwa matibabu ya kati au kuchakata tena.

Usafi wa granules za mpira uliomalizika au poda inaweza kuwa juu kama 99%, kuhakikisha ubora na utulivu wa matumizi ya baadaye.

Vipengele muhimu vya laini ya kuchakata taka

- Utunzaji wa ukubwa wa tairi: Iliyoundwa maalum kwa matairi na kipenyo cha chini ya 1200mm, pamoja na matairi ya gari, matairi ya lori, na matairi nyepesi ya OTR.

- Bidhaa za Mwisho: Inazalisha 1-5mm granules za mpira au poda ya mpira wa mesh 10-40, inafaa kwa anuwai ya matumizi.

- Uwezo rahisi: Uwezo wa kushughulikia mahitaji ya uzalishaji kutoka tani chache hadi tani kadhaa kwa siku, kukidhi mahitaji ya shughuli ndogo na kubwa za kuchakata.

- Mchakato wa moja kwa moja: Hupunguza gharama za kazi na huongeza ufanisi wa uzalishaji na kufikisha smart, uhifadhi, na mifumo ya utenganisho wa nyenzo.

Suluhisho tatu za matibabu ya mapema zinapatikana

Kukidhi mahitaji tofauti ya wateja na hali ya nyenzo, tunatoa chaguzi tatu za matibabu kabla ya hatua nzuri ya kusaga mpira:

1, Tiro DeBeader + Tiro Cutter + Shredder Line

- Kondakta wa Taya: Huondoa nyuzi za chuma kutoka kwa mipako ya taya.

- Kutter för däck: Klipper däck i mindre sektioner.

- Mashine ya Kukata Taya: Hukatakata sehemu za taya kuwa vizuizi vya goma.

- Kondakta wa Kati: Hupeleka vifaa kiotomatiki.

- Mfumo wa Hifadhi ya Vizuizi vya Goma: Huhifadhi vizuizi vya goma vilivyokatwa.

- Kondakta wa Kutolewa Kiotomatiki: Hupeleka vifaa kwenye mashine ya unga wa goma.

- Kikata Goma: Huponda vizuizi kuwa chembe au unga.

- Fiberseparator: Separera nylonfibrer.

- Mfumo wa Kukusanya Goma: Hukusanya na kuhamasisha bidhaa za mwisho.

2, Mashine ya Kukata Mipako ya Taya na Kukata Taya + Separata ya Nyaya za Chuma + Mstari wa Kukata Taya

- Mashine ya Kukata Mipako na Kukata Taya: Inajumuisha kukata mipako ya taya na sehemu za taya.

- Separatare för ståltråd: Separera den inbäddade ståltråden effektivt.

- Skräddare och efterföljande system är desamma som Lösning 1.

3, Direkt shredding-linje

- Däckshredder: Krossa däcket direkt i små bitar. Lämplig för däck som har förskurits eller har fått beadsen borttagna.

- Iliyofuatiwa na conveyor ya kati, mfumo wa kuhifadhi, conveyor ya kutolea, crusher ya mpira, separator ya nyuzi, na mfumo wa ukusanyaji kama ilivyo katika suluhisho zingine.

Varför välja vår helt automatiska återvinningslinje för avfall däck?

- Hög automatisering: Minimera manuellt arbete och maximera stabiliteten i produktionen.

- Modulär design: Lätt att anpassa efter specifika råmaterial och krav på slutprodukten.

- Effektiv Separation: Högpurity gummigranulat och pulver med ståltråd och fiberinnehåll reducerat till minimala nivåer.

- Pålitlig Prestanda: Byggd med hållbara komponenter för långsiktig, kontinuerlig drift.