A nossa linha de reciclagem de pneus usados totalmente automática é uma solução avançada projetada para processar pneus descartados em grânulos de borracha limpos e de alta qualidade ou pó de borracha, com intervenção manual mínima. O sistema alcança total automação desde a trituração, moagem, triagem, separação magnética, separação de fibras, até a coleta final do material.

Matérias-Primas

As nossas linhas de reciclagem de pneus totalmente automatizadas são especificamente projetadas para processar todos os tipos de pneus em fim de vida com um diâmetro inferior a 1200mm, incluindo pneus de automóveis, pneus de camiões e pneus de engenharia leve. Para pneus maiores, como os pneus OTR, também oferecemos soluções correspondentes.

Produto Acabado

Após ser processada pela linha de reciclagem de pneus de resíduos totalmente automática, os seguintes produtos acabados podem ser obtidos:

- Grânulos de borracha (1-5mm): utilizados para pista de corrida, preenchimento de gramados e fabricação de produtos de borracha.

- Pó de borracha (10-40 mesh): para produção de borracha reciclada e processamento de produtos de borracha.

- Fio de aço: recuperados por separação magnética, usados como matéria-prima para fusão ou reprocessamento.

- Impurezas de fibra: separados por separação a ar, conveniente para tratamento ou reciclagem centralizada.

A pureza das granulações ou pó de borracha acabados pode ser de até 99%, garantindo qualidade e estabilidade para aplicações subsequentes.

Principais Características da Linha de Reciclagem de Pneus Usados

- Manipulação de Tamanhos de Pneus: Projetado especialmente para pneus com diâmetro de menos de 1200mm, incluindo pneus de carro, pneus de caminhão e pneus OTR leves.

- Produtos Finais: Produz granulados de borracha de 1-5mm ou pó de borracha de 10-40 mesh, adequado para uma ampla gama de aplicações.

- Capacidade FlexívelCapaz de lidar com requisitos de produção de algumas toneladas a várias dezenas de toneladas por dia, atendendo às necessidades de operações de reciclagem tanto pequenas quanto grandes.

- Processo Totalmente Automatizado: Reduz os custos de mão de obra e aumenta a eficiência da produção com sistemas inteligentes de transporte, armazenamento e separação de materiais.

Três Soluções de Pré-tratamento Disponíveis

Para atender diferentes necessidades dos clientes e condições de materiais, oferecemos três opções de pré-tratamento antes da etapa de moagem fina de borracha:

1, Desmontador de Pneus + Cortador de Pneus + Linha de Trituradores

- Desmontador de Pneus: Remove fios de aço dos bordos dos pneus.

- Cortador de Pneus: Corta pneus em seções menores.

- Triturador de Pneus: Tritura seções de pneus em blocos de borracha.

- Transportador Intermediário: Transfere materiais automaticamente.

- Sistema de Armazenamento de Blocos de Borracha: Armazena blocos de borracha triturados.

- Transportador de Descarregamento Automático: Alimenta material na máquina de pó de borracha.

- Triturador de Borracha: Moer blocos em grânulos ou pó.

- Separador de Fibras: Separa fibras de nylon.

- Sistema de Coleta de Borracha: Coleta e transfere produtos finais.

2, Cortador de Bead Integrado & Cortador de Pneus + Separador de Fios de Aço + Linha de Triturador de Pneus

- Máquina de Corte de Bead e Corte de Pneus: Integra o corte de beads de pneus e seções de pneus.

- Separador de Fios de Aço: Separa eficientemente o fio de aço embutido.

- O triturador e os sistemas subsequentes são os mesmos que a Solução 1.

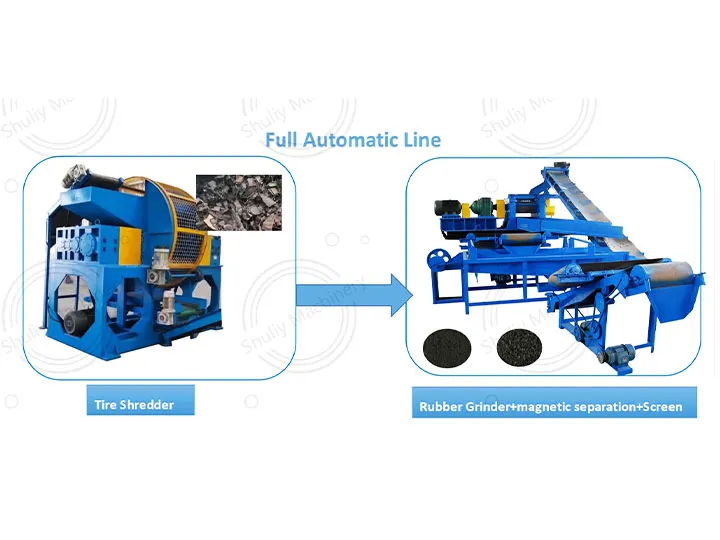

3, Linha de Trituração Direta

- Máquina de Trituração de Pneus: Tritura o pneu diretamente em pequenos pedaços. Adequada para pneus que foram pré-cortados ou que tiveram os beads removidos.

- Seguido pelo transportador intermediário, sistema de armazenamento, transportador de descarga, triturador de borracha, separador de fibras e sistema de coleta, como nas outras soluções.

Por que escolher nossa linha de reciclagem de pneus usados totalmente automática?

- Alta Automação: Minimizar o trabalho manual e maximizar a estabilidade da produção.

- Design Modular: Fácil de personalizar de acordo com matérias-primas específicas e requisitos de produtos finais.

- Separação Eficiente: Grânulos e pó de borracha de alta pureza com conteúdo de fio de aço e fibra reduzido a níveis mínimos.

- Desempenho Fiável: Construído com componentes duráveis para operação contínua a longo prazo.