Jalur pencucian botol PET Shuliy Machinery adalah solusi lengkap untuk mendaur ulang botol PET. Melalui serangkaian peralatan pencacahan, pencucian, dan pengeringan yang canggih, botol PET akhirnya diproses menjadi serpihan PET yang bebas kontaminasi. Jalur daur ulang botol PET standar kami memiliki kapasitas 500kg/jam-6000kg/jam, dan kami dapat menyesuaikan konfigurasi dan kapasitas peralatan jalur sesuai dengan kebutuhan Anda.

Jika Anda ingin memulai bisnis daur ulang botol PET, berinvestasi pada mesin daur ulang botol PET adalah pilihan yang baik, pabrik daur ulang botol PET kami telah diekspor ke Nigeria, Mozambik, Kongo, Arab Saudi, dan negara lain.

Pengenalan Jalur Daur Ulang Botol PET

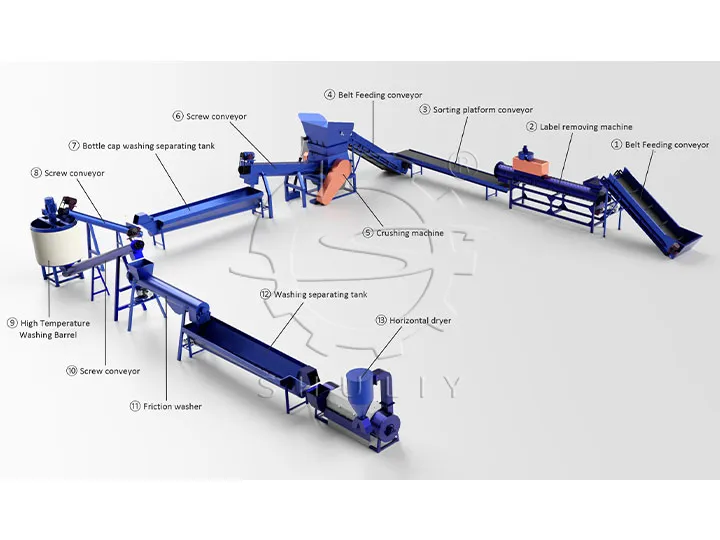

Peralatan utama dari pabrik daur ulang botol PET ini meliputi alat penghilang label botol PET, mesin penghancur botol plastik, tangki tenggelam mengapung plastik, tangki pencucian panas, pencuci gesekan plastik, dan pengering horizontal. Untuk memastikan kualitas serpihan PET akhir, Anda memilih beberapa langkah pencucian.

Mesin cuci botol PET ini terutama digunakan untuk mencuci dan mendaur ulang botol plastik berbahan PET seperti botol air mineral, botol minuman, botol susu, dan lain sebagainya. Serpihan botol ini selanjutnya dapat digunakan untuk reproduksi atau pembuatan pelet, yang banyak digunakan dalam industri manufaktur plastik. Mesin bekas botol plastik kami cocok untuk perusahaan dari semua ukuran dan dapat disesuaikan sesuai dengan kebutuhan spesifik pelanggan untuk memastikan pengoperasian yang efisien dan keluaran lini produksi berkualitas tinggi.

Keuntungan Mesin Daur Ulang Botol PET

- Kemampuan pembersihan dengan efisiensi tinggi: Pastikan permukaan dan kotoran internal botol PET dihilangkan secara menyeluruh untuk meningkatkan kualitas serpihan botol daur ulang.

- Konfigurasi fleksibel: Jalur pencucian botol PET dapat disesuaikan sesuai dengan kebutuhan spesifik pelanggan, volume produksi, dan tata letak pabrik untuk memberikan solusi terbaik.

- Persyaratan kualitas: Pastikan kekeringan, nilai pH, viskositas karakteristik, kandungan PVC, dll. dari serpihan botol PET akhir yang diproduksi memenuhi standar.

Bahan Baku dan Produk Akhir dari Jalur Pencucian Botol PET

Bahan baku pabrik daur ulang botol PET adalah segala jenis limbah botol PET, seperti botol air mineral, botol minuman, botol jus, botol susu, botol bir, dll. Produk akhirnya adalah serpihan botol PET daur ulang.

Kualitas serpihan botol PET daur ulang dapat diklasifikasikan berdasarkan warna, dari tinggi ke rendah, menjadi serpihan putih murni, serpihan biru muda, serpihan hijau, serpihan kuning, dan serpihan lain-lain. Bagi pendaur ulang, serpihan botol berkualitas tinggi setelah klasifikasi dan pembersihan yang ketat dapat memenuhi permintaan pasar kelas atas dan meningkatkan nilai produk.

Pelajari lebih lanjut: Faktor yang Mempengaruhi Fluktuasi Harga Daur Ulang Serpihan Botol PET

Video Kerja Pabrik Daur Ulang Botol PET

Langkah Daur Ulang Jalur Pencucian Serpihan PET

Alur kerja jalur pencucian serpihan PET biasanya mencakup langkah-langkah penting berikut.

- Mengumpulkan botol PET: Pertama, kumpulkan botol PET bekas dari berbagai sumber seperti tempat daur ulang, supermarket, restoran, dan rumah tangga.

- Membongkar: Botol plastik yang dikumpulkan dari tempat pembuangan sampah biasanya perlu dibongkar terlebih dahulu.

- Penghancuran: Botol PET yang telah disortir dimasukkan ke dalam mesin penghancur botol plastik untuk dipotong menjadi serpihan guna memperkecil ukurannya.

- Pembersihan: Mencuci serpihan botol PET untuk menghilangkan kotoran permukaan, minyak, dan label. Hal ini dapat mencakup beberapa tahap pencucian untuk memastikan serpihan botol menjadi bersih.

- Pengeringan: Mengeringkan pelet PET yang telah dicuci untuk menghilangkan sisa kelembapan dan memastikan memenuhi standar kualitas.

Video 3D Jalur Pencucian Botol PET

Video menunjukkan proses daur ulang botol PET 1000kg/jam. Mesin daur ulang botol PET kami tersedia dalam berbagai macam keluaran untuk memenuhi kebutuhan sebagian besar pendaur ulang.

Mesin Daur Ulang Botol PET Utama

Penghilang Label Botol PET: Langkah pertama dari lini daur ulang botol PET biasanya adalah menghilangkan label PVC. Penghilang label botol PET dapat secara efektif menghapus label, tingkat penghilangan label mencapai 98%, dengan tingkat otomatisasi yang tinggi, alih-alih menghapus label secara manual.

Mesin Penghancur Botol Plastik: Mesin ini digunakan untuk menghancurkan botol plastik menjadi serpihan botol untuk pencucian dan daur ulang selanjutnya. Material pisau mesin penghancur botol plastik adalah 9Crsi untuk umur yang panjang.

Tangki Pemisahan Tenggelam Mengapung Plastik: Peralatan ini digunakan untuk memisahkan serpihan botol PET dari tutup atau label. Saat digunakan, serpihan botol PET akan tenggelam dan diangkut ke langkah berikutnya melalui sekrup di bagian bawah, sementara label atau tutup akan mengapung di permukaan air.

Tangki Pencucian Panas: Tangki pencucian panas membersihkan serpihan botol PET melalui air bertekanan tinggi dengan deterjen kimia. Ini lebih efektif daripada pencucian dingin, dapat secara efektif menghilangkan kehadiran atau ketiadaan serta sisa-sisa perekat, dll.

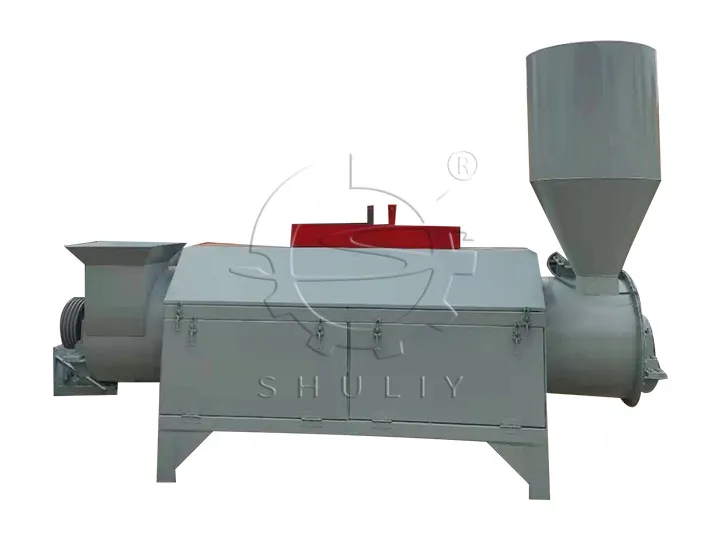

Pencuci Gesekan Plastik: Di dalam mesin, terdapat beberapa pelat gosok dan strip gosok untuk mencuci deterjen yang dibawa keluar dari tangki pencucian panas dan menurunkan tingkat pH.

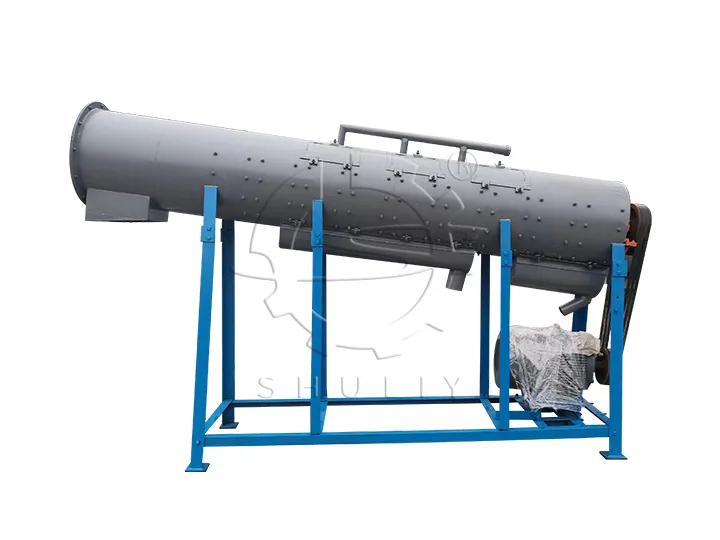

Pengering Horizontal: Mesin ini dapat menghilangkan 98% air dalam serpihan botol PET, dan dengan tabung pengering di belakang, kandungan air dapat dikendalikan pada 0,5-1%.

Parameter Jalur Daur Ulang Botol PET 1000kg/jam

Di bawah ini adalah informasi tentang parameter beberapa mesin pabrik daur ulang botol PET, kami juga memiliki banyak model dan keluaran mesin yang berbeda-beda. Jika Anda membutuhkannya, silakan tinggalkan informasi Anda dalam formulir di situs web kami, dan kami akan segera mengirimkan detail mesin kepada Anda.

| Barang | Spesifikasi | Jumlah |

| Penghapus label botol PET | Tegangan: 380V, 50HZ, listrik 3 fase Daya: 15+3+1,5kw Panjang barel: 4,3m, diameter: 0,63m Tarif botol bulat di luar label 98% Kandungan PVC/(mg/kg) ≤ 100-300 (mg/kg) | 1 |

| Mesin penghancur botol plastik | Tegangan: 380V, 50HZ, listrik 3 fase Daya: 37+1,5KW+1,5kw Alat: 9Crsi Produksi: 1000KG/JAM Ukuran layar: 18mm Ketebalan pelat pisau: 40mm | 1 |

| Tangki wastafel pelampung plastik | Tegangan: 380V, 50HZ, listrik 3 fase Daya: 3KW Ketebalan dinding luar: 4mm Ketebalan pisau: 6mm Ukuran peralatan: 5000*1000*1000mm | 3 |

| Tangki cuci panas | Tegangan: 380V, 50HZ, listrik 3 fase Motor 4kw Daya pemanas elektromagnetik: 80KW Tinggi: 2000mm, diameter: 1300mm | 2 |

| Mesin cuci gesekan | Tegangan: 380V, 50HZ, listrik 3 fase Daya: 7,5KW Panjang barel: 3000mm, diameter: 400mm Ketebalan pisau: 6mm | 2 |

| Mesin dewatering plastik | Tegangan: 380V, 50HZ, listrik 3 fase Daya: 15KW Hilangkan kelembapan dan capai tingkat pengeringan sekitar 95-98% | 1 |

| Mengeringkan pipa | Tegangan: 380V,50HZ, listrik 3fase Diameter 159mm, panjang 15m Daya pemanas 30kw, pemanasan dengan kelembaban 0,5% Motor 7.5+3kw Bahan kontak bagian baja tahan karat 304 Kelembaban (%)≤0,5-1% | 1 |

| Pemisah angin | Tegangan: 380V,50HZ, listrik 3 fasa Diameter 0,8m, tinggi 4,5m; Motor 2.2kw3 Kipas tambahan: 0,753 Motor lift 3kw Untuk menghilangkan sisa merek halus dan debu Kandungan pengotor/(mg/kg)≤300-500 Kandungan bubuk/(mg/kg)≤2000-3000 | 1 |

Di atas adalah parameter rinci peralatan utama jalur pencucian botol PET 1000kg/jam. Diantaranya, saluran pengeringan dan pemisah udara cocok untuk skenario dengan keluaran besar dan persyaratan kualitas tinggi untuk serpihan botol PET.

Kasus Sukses Jalur Pencucian Botol PET

Mesin Daur Ulang Plastik PET Khusus Dikirim ke Nigeria

Mesin daur ulang plastik PET kami yang disesuaikan telah berhasil dikirim ke Nigeria dan kami akan terus memantau kinerja mesin tersebut di pabrik Nigeria.

Untuk detail lebih lanjut, silakan lihat: Lini Pencucian Serpihan Botol PET Telah Dikirim ke Nigeria

Jalur Pencucian Serpihan PET Dikirim ke Kongo

Seorang pelanggan dari Kongo telah membeli mesin pencuci serpihan PET lengkap dari Shuliy Machinery, yang sekarang beroperasi secara lokal.

Untuk detail lebih lanjut, silakan lihat: Pabrik Pencucian Botol PET Diekspor ke Kongo

Pabrik Daur Ulang Botol PET Dikirim ke Mozambik

Sebelumnya, pelanggan dari Mozambik mengkustomisasi pabrik daur ulang botol PET di Shuliy Machinery, berikut video pengirimannya.

Untuk detail lebih lanjut, silakan lihat: Lini Daur Ulang Botol PET Diekspor ke Mozambik

Produsen Jalur Pencucian Botol PET Terbaik

Apakah Anda mencari produsen lini pencucian botol PET terbaik? Kami berkomitmen untuk menyediakan pemasok mesin daur ulang botol hewan peliharaan berkualitas tinggi untuk memenuhi kebutuhan Anda. Produk kami memenuhi standar industri dan memberikan solusi andal untuk daur ulang botol plastik. Jika Anda mencari produsen terpercaya, kami akan dengan senang hati memberi Anda layanan profesional.