Sebagai peralatan penting dalam lini produksi pelet plastik, pengoperasian normal mesin pemotong pelet plastik sangat penting untuk efisiensi produksi. Untuk memastikan mesin dapat terus bekerja secara efisien, pemeliharaan dan perawatan yang tepat sangatlah penting. Di bawah ini kami akan memperkenalkan cara merawat mesin pemotong butiran plastik.

Pembersihan dan Pelumasan Reguler

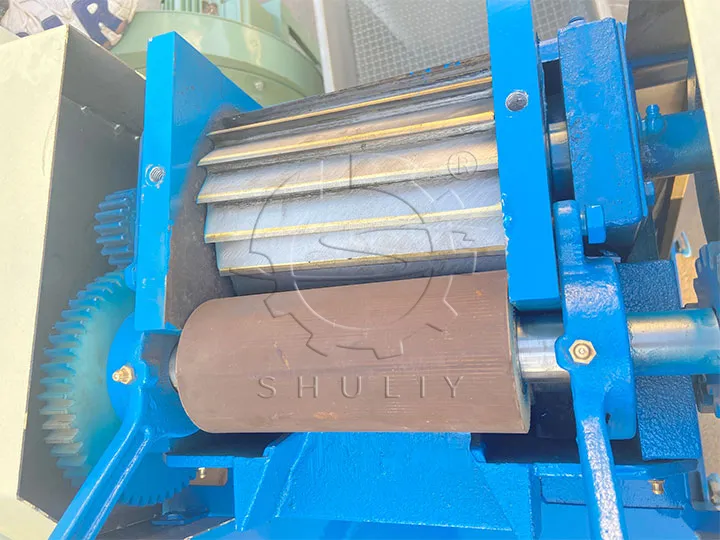

Pertama, pembersihan rutin merupakan salah satu langkah penting agar mesin pemotong pelet plastik tetap berfungsi dengan baik. Penghapusan debu, residu, dan kotoran lainnya secara tepat waktu pada permukaan dan bagian dalam mesin dapat mencegah kotoran menyumbat mesin dan mempengaruhi efek pemotongan. Selain itu, pelumasan rutin pada bilah dan kompor juga penting untuk mengurangi gesekan dan keausan serta memperpanjang masa pakai pisau.

Pemeliharaan Pisau Mesin Pemotong Pelet Plastik

Kedua, pemeriksaan dan penyesuaian rutin berbagai komponen mesin pemotong butiran plastik juga merupakan salah satu elemen penting dalam perawatan. Periksa ketajaman dan keausan mata pisau dan ganti mata pisau yang sudah sangat aus tepat waktu untuk memastikan efek pemotongan.

Menurut pengalaman, pada umumnya, pemotong granul plastik memerlukan penggantian pisau setiap kali memotong sekitar 2.000 ton pelet. Karena penggunaan jangka panjang akan menyebabkan keausan serius pada pisau, mempengaruhi efek pemotongan dan produktivitas. Oleh karena itu, penggantian pisau tepat waktu adalah salah satu langkah kunci untuk menjaga mesin pemotong pelet plastik tetap berjalan efisien.

Kesimpulan

Memelihara pemotong butiran plastik Anda adalah kunci untuk menjaga lini produksi pelet plastik Anda berjalan secara efisien. Pembersihan dan pelumasan secara teratur, pemeriksaan dan penyesuaian berkala, serta penggantian bilah tepat waktu dapat memastikan pengoperasian normal alat berat Anda, meningkatkan produktivitas, dan mengurangi biaya perawatan. Kami berharap panduan perawatan di atas dapat membantu Anda mengelola dan merawat mesin pemotong pelet plastik Anda dengan lebih baik untuk memastikan pengoperasiannya stabil dalam waktu lama.