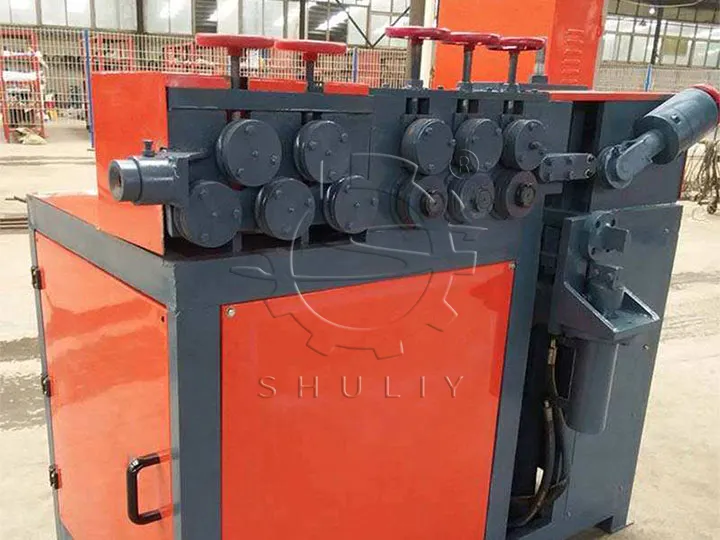

Nuestra máquina de doblado de espirales de varillas de acero está diseñada para el procesamiento continuo de barras de acero, integrando alimentación, enderezado, doblado (formación en espiral) y corte en un flujo de trabajo automatizado. La máquina utiliza un sistema de control PLC para garantizar una precisión de ±0,2 mm y ofrece varios modelos adecuados para diámetros de barras de 3 mm a 25 mm.

¿Qué es una máquina para fabricar anillos de acero?

Una máquina de doblado de espirales de varillas de acero se utiliza para producir anillos circulares, barras en espiral y componentes de acero en forma de bobina para aplicaciones como puentes de ferrocarril de alta velocidad, proyectos de metro, cimientos fotovoltaicos y pilotes de anclaje en tierra.

La máquina soporta automatización completa, procesamiento por lotes y conformado a alta velocidad, lo que la hace adecuada tanto para sitios de construcción como para fábricas de procesamiento de acero.

Características principales de la máquina de doblado de espirales de varillas de acero

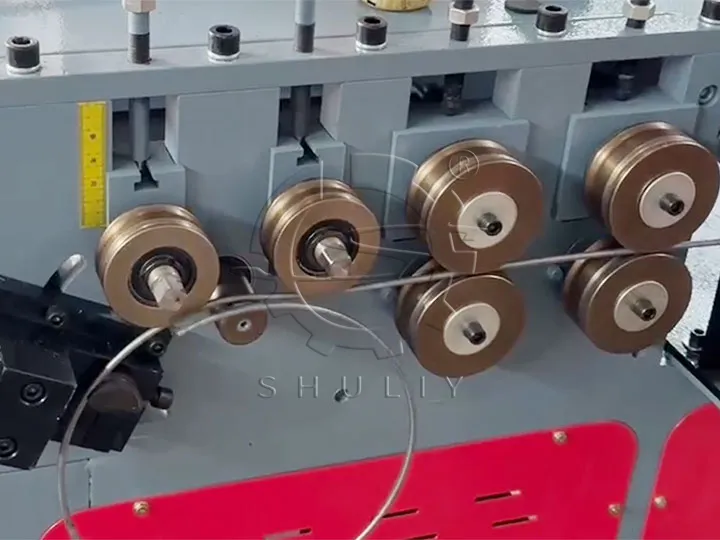

- Alimentación–Enderezado–Doblado–Corte integrados: La máquina de fabricación de anillos de acero combina todos los pasos del proceso, reduciendo la mano de obra y mejorando la eficiencia de producción.

- Sistema de control PLC de alta precisión: El sistema PLC controla cada movimiento con una precisión de ±0,2 mm, garantizando una calidad de conformado constante.

- Amplio rango de procesamiento: 3–25 mm: Varios modelos permiten a los clientes elegir la máquina adecuada para diferentes diámetros de varillas y requisitos de producción.

- Adecuado para producción continua y por lotes: La máquina puede procesar automáticamente un paquete de barras de acero, soportando operación continua.

Principio de funcionamiento de la máquina de hacer anillos de barras de acero

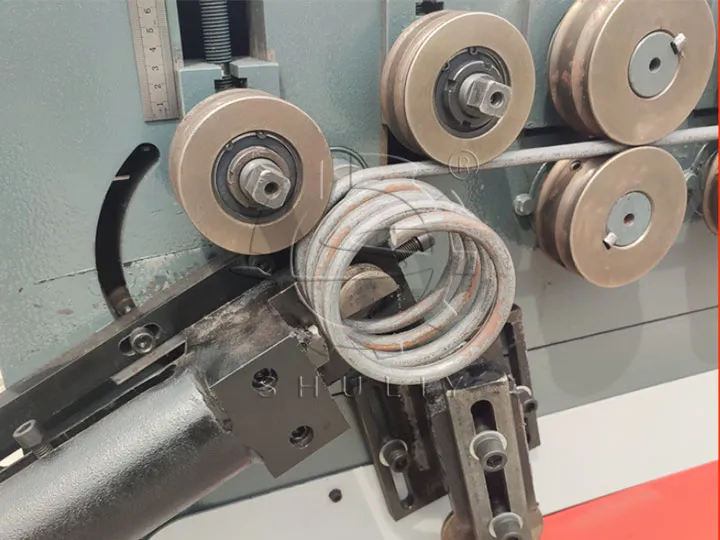

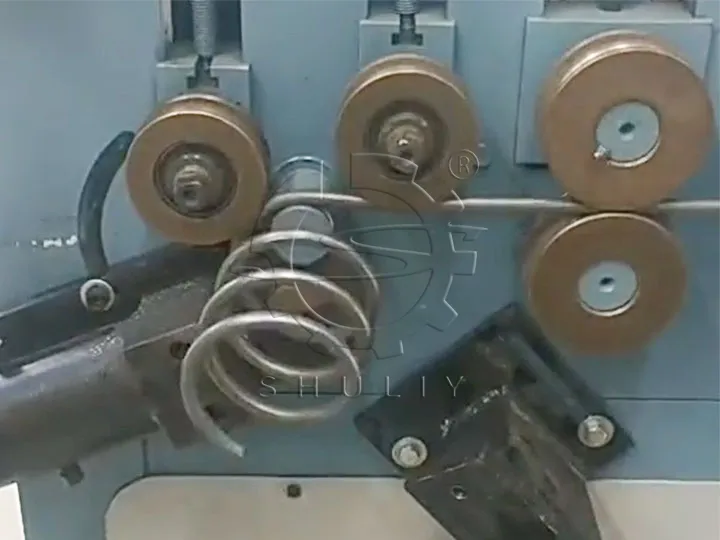

El sistema PLC inicia el motor para accionar la bomba hidráulica, activando los componentes hidráulicos que alimentan la caja de engranajes de enderezado. La barra de acero se alimenta hacia adelante, pasa por la unidad de enderezado y luego entra en el conjunto de conformado donde se forma la espiral o forma circular.

Después de completar el doblado, la unidad de corte opera hacia arriba para cortar la barra de acero, finalizando todo el ciclo de procesamiento.

Especificaciones del modelo de la dobladora de espirales para barras de refuerzo

| Modelo | Diámetro de la barra de acero | Diámetro del anillo | Potencia Total | Velocidad | Error | Tamaño | Peso |

| 3–6 | 3–6 mm | 50–1000 mm | 4 kW | 16–25 m/min | ±0,2 mm | 1,45×0,8×1,2 m | 480 kg |

| 6–10 | 6–10 mm | 50–800 mm | 5,5 kW | 16–25 m/min | ±0,2 mm | 1,55×0,8×1,3 m | 560 kg |

| 8–12 | 8–12 mm | 50–1500 mm | 7 kW | 16–25 m/min | ±0,2 mm | 1,55×0,8×1,3 m | 640 kg |

| 10–14 | 10–14 mm | 50–1800 mm | 7 kW | 16–25 m/min | ±0,2 mm | 1,6×0,8×1,35 m | 690 kg |

| 16–20 | 16–20 mm | 50–2200 mm | 11 kW | 16–30 m/min | ±0,2 mm | 2,1×0,9×1,5 m | 1150 kg |

| 22–25 | 22–25 mm | 50–3000 mm | 15 kW | 16–30 m/min | ±0,2 mm | 2,3×0,9×1,7 m | 1350 kg |

Aplicaciones de la dobladora de espirales para barras de refuerzo

- Varillas espirales para ferrocarril de alta velocidad

- Anillos de refuerzo para metro

- Anclajes de fundación fotovoltaica

- Estribos de construcción y soportes circulares

- Fábricas de procesamiento de acero y fabricación de metales

Equipamiento relacionado para el procesamiento de barras de refuerzo

Para apoyar flujos de trabajo completos de procesamiento de barras de acero, también ofrecemos equipos como la máquina de enderezado de barras, dobladora de estribos de barras de refuerzo y dobladora de tubos CNC. Cualesquiera que sean sus requisitos para procesar barras de refuerzo de acero, le recomendamos el equipo más adecuado para usted.

Solicite una cotización para la máquina de hacer anillos de acero

Si necesita una dobladora de espirales de refuerzo confiable para construcción o procesamiento de acero, no dude en contactarnos. Ofrecemos soporte en la selección de modelos, pruebas en fábrica, suministro de piezas de repuesto y asistencia técnica en el extranjero.