Máy chỉnh hình thép là thiết bị thiết yếu để xử lý thép uốn cong hoặc thép phế liệu, được sử dụng rộng rãi trong các nhà máy tái chế thép và chuẩn bị vật liệu xây dựng. Công ty chúng tôi cung cấp một loạt các giải pháp chỉnh hình thép, bao gồm nhiều mẫu máy cho thép từ 6–25 mm, cổng cấp liệu tùy chỉnh, con lăn bền bỉ và hệ thống động cơ đôi mạnh mẽ để đảm bảo hiệu suất chỉnh hình ổn định và hiệu quả. Chúng tôi cũng cung cấp hướng dẫn chọn mẫu, kiểm tra tại nhà máy, cung cấp phụ tùng thay thế và hỗ trợ kỹ thuật quốc tế, giúp khách hàng nhanh chóng vận hành máy.

Các tính năng chính của máy chỉnh hình thép

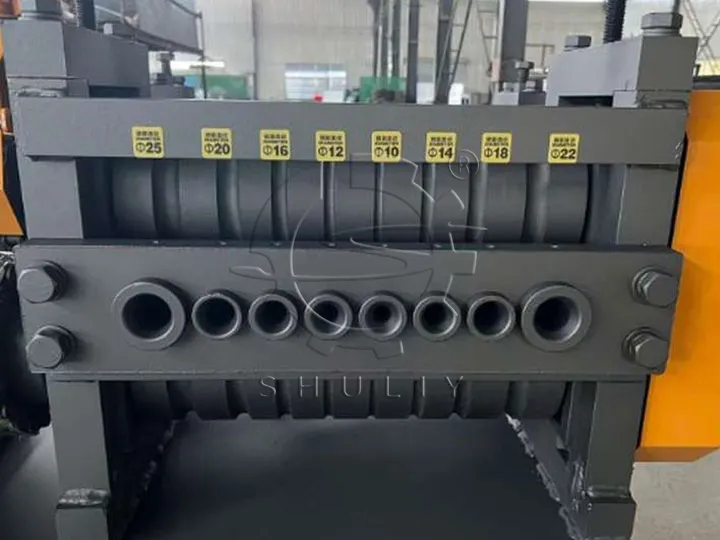

Nhiều lỗ cấp liệu cho các đường kính khác nhau

Mỗi mẫu đều đi kèm nhiều lỗ cấp liệu. Người vận hành chỉ cần chọn lỗ phù hợp với đường kính thép để cấp liệu trơn tru.

Ngoài các lỗ tròn, các cổng cấp liệu dạng T cũng có sẵn để cấp liệu nhanh hơn và dễ dàng hơn.

Con lăn chỉnh hình dày bền bỉ

Máy sử dụng con lăn chịu mài mòn dày hơn, kéo dài tuổi thọ và giảm chi phí thay thế.

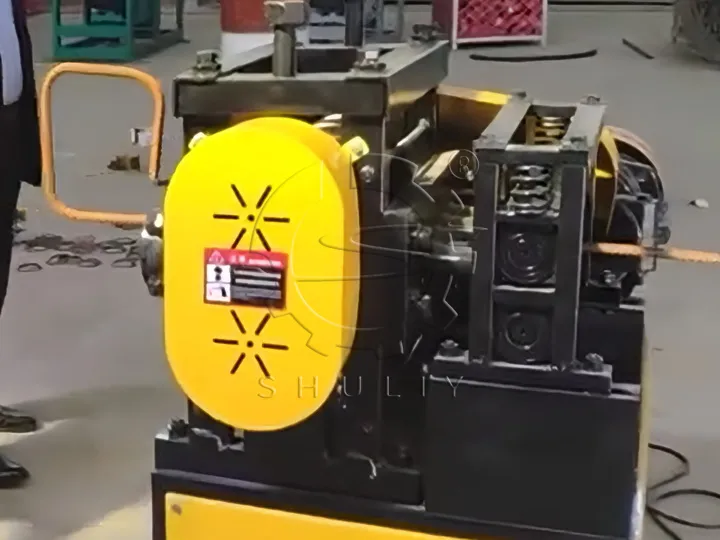

Hệ thống truyền động đôi ổn định và hiệu quả cao

Cấu hình động cơ đôi mang lại lực chỉnh hình mạnh mẽ, cho phép vận hành liên tục với năng suất ổn định.

Nguyên lý hoạt động của máy chỉnh hình thép

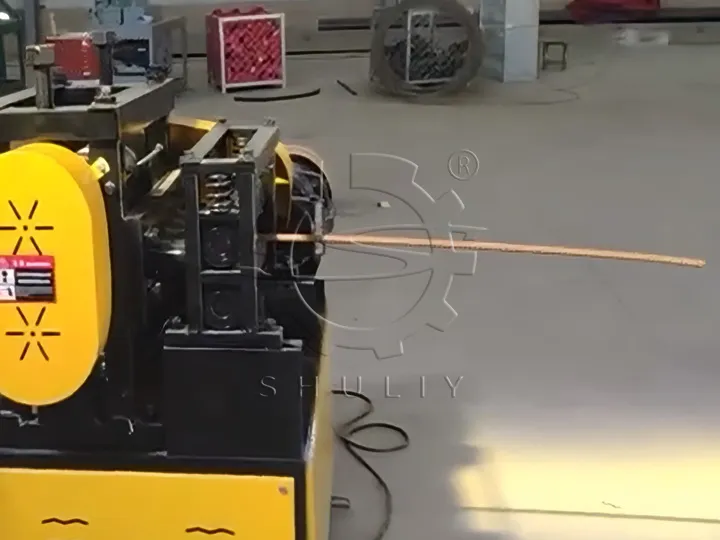

Máy chỉnh hình thép hoạt động bằng cách cấp thép uốn cong hoặc thép phế liệu qua nhiều con lăn chỉnh hình được điều khiển bởi hệ thống động cơ đôi và hộp giảm tốc. Khi thép đi qua lỗ cấp liệu đã chọn, các con lăn quay với tốc độ cao, áp dụng lực liên tục để loại bỏ các uốn cong và khôi phục thép về trạng thái thẳng.

Các con lăn dày của máy đảm bảo lực ổn định trong quá trình chỉnh hình, trong khi lỗ cấp liệu phù hợp hoặc tùy chọn đầu vào dạng T giúp hướng dẫn các đường kính khác nhau vào hệ thống một cách trơn tru. Sau khi chỉnh hình, thép tự động được chuyển đến phần xả để thu gom hoặc xử lý tiếp theo.

Các mẫu và thông số kỹ thuật của Máy uốn thép

| Người mẫu | Đường kính thanh uốn thẳng | Lỗ cấp liệu | Chiều dài uốn thẳng | Công suất động cơ | Trọng lượng máy | Kích thước máy |

| 6-10 | 6-10 mm | 5 lỗ | 500–2000 mm | 4 kW | 570 kg | 1100×720×1150 mm |

| 6-14 | 6-14 mm | 5 lỗ | 500–2000 mm | 5 kW | 730 kg | 1200×789×1220 mm |

| 8-16 | 8-16 mm | 5 lỗ | 500–2000 mm | 5 kW | 750 kg | 1250×820×1300 mm |

| 14-25 | 14-25 mm | 6 lỗ | 500–2000 mm | 15 kW | 980 kg | 1550×890×1600 mm |

Ứng dụng của Máy Uốn Thẳng Thép

- Tái chế thép phế thải

- Tái sử dụng thép tại công trường xây dựng

- Xưởng chế biến thép

- Uốn thép phế thải

- Cơ sở tái chế kim loại

Máy uốn thép này giúp phục hồi thép bị uốn cong hoặc bỏ đi, nâng cao hiệu quả sử dụng vật liệu và giảm thiểu chất thải.

Tại sao chọn Máy uốn thép của chúng tôi?

- Hỗ trợ phạm vi uốn thẳng rộng (6–25 mm)

- Hệ truyền động kép mạnh mẽ với hiệu suất mượt mà

- Nhiều lỗ cấp liệu tùy chọn đầu vào dạng T

- Bánh xe chịu lực cho tuổi thọ dài

- Vận hành ổn định với tỷ lệ lỗi thấp

Yêu cầu báo giá cho Máy uốn thép

Nếu bạn cần một máy uốn thép đáng tin cậy để xử lý và tái chế thép, hãy liên hệ với chúng tôi. Đội ngũ của chúng tôi sẽ đề xuất mô hình phù hợp dựa trên đường kính thép của bạn, yêu cầu về sản lượng và ngân sách.

Thiết bị xử lý thép liên quan

Để hỗ trợ nhu cầu xử lý thép hoàn chỉnh, chúng tôi cũng cung cấp các máy móc xử lý thép liên quan. Bao gồm máy tạo vòng thép để tạo vòng tròn, máy uốn vòng thép để tạo hình vòng thép xây dựng, và máy uốn ống CNC để uốn chính xác ống hoặc ống dẫn. Thiết bị của chúng tôi phục vụ nhiều yêu cầu xử lý khác nhau. Nếu bạn cần dịch vụ của chúng tôi, xin đừng ngần ngại liên hệ.