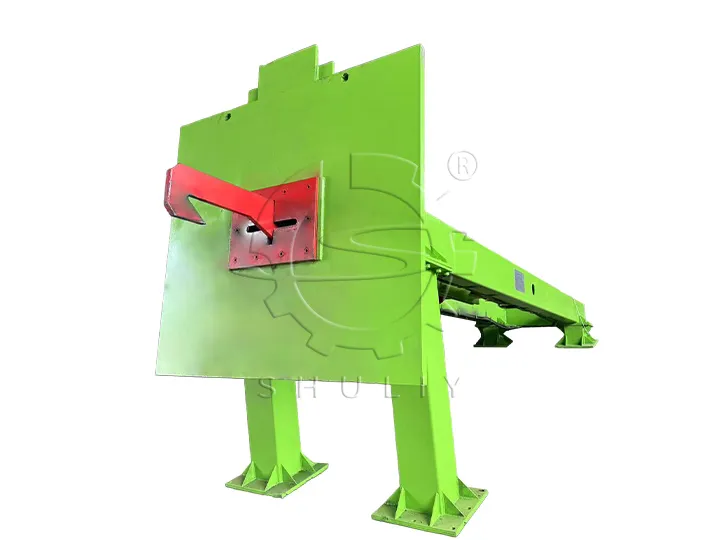

Наша тяжелая OTR машина для удаления бортовой проволоки — это основное решение для переработки крупногабаритных карьерных шин, обеспечивающее мощный и эффективный способ извлечения высокопрочной стальной бортовой проволоки. Для любого серьезного предприятия по переработке OTR шин предварительная обработка этих гигантских шин с удалением прочного внутреннего стального кольца — не просто рекомендация, а необходимость для защиты оборудования на следующих стадиях и увеличения стоимости перерабатываемых материалов.

Проблема переработки OTR шин

Карьерные шины, используемые в горнодобывающей, строительной и сельскохозяйственной технике, рассчитаны на экстремальную износостойкость. Их бортовые проволоки — толстые пучки высокопрочной стали — значительно больше и прочнее, чем у обычных грузовых шин. Попытки измельчить такие шины целиком могут привести к катастрофической поломке дорогостоящих шинорезов, вызывая дорогостоящие простои и ремонты. Здесь становится незаменимой специализированная машина для удаления стальной проволоки из OTR шин.

Обзор продукта: 4-метровый OTR дебидер

Наш 4-метровый OTR дебидер специально разработан для работы с чрезвычайно сложной задачей вытягивания бортовой проволоки из шин диаметром от 1800 мм до 4000 мм. Его прочная конструкция и мощная гидравлическая система гарантируют надежную и стабильную работу даже в самых сложных условиях.

Ключевые преимущества и особенности:

- Мощная гидравлическая система: Оснащена силовой установкой мощностью 22 3 кВт, машина создает огромную силу тяги, легко извлекая даже самые упрямые проволоки без предварительной резки шины.

- Широкий диапазон обработки: Способна обрабатывать широкий диапазон размеров шин, от 1800 мм до 4000 мм, что делает ее универсальным решением для предприятий, перерабатывающих различные типы тяжелых шин.

- Высокая эффективность: При цикле примерно 2 минуты за один вытягивание эта машина значительно увеличивает пропускную способность всей линии переработки, обеспечивая стабильный поток дебейдированных шин для следующего этапа.

- Прочная и надежная конструкция: Наш ободный дебейдер весом 9500 кг изготовлен из толстостенной стали, чтобы выдерживать огромные силы, участвующие в процессе дебейдинга, что гарантирует долгий срок службы и высокий возврат инвестиций.

- Защищает оборудование на следующем этапе: Удаляя сначала стальную проволоку, вы значительно снижаете износ и повреждения ваших основных дробилок, что увеличивает их срок службы и снижает общие затраты на обслуживание.

Принцип работы OTR машины для удаления бортовой проволоки

Этот дебидер использует мощное гидравлическое усилие для принудительного вытягивания толстой стальной проволоки из борта OTR шины. Конкретный рабочий процесс следующий:

- Положение шины: Используя оборудование, такое как погрузчик или кран, обрабатываемая гигантская шина OTR размещается в рабочем положении перед машиной.

- Операция зацепления: Оператор протягивает прочный специализированный крюк машины через отверстие в основном корпусе и надежно зацепляет его за внутреннюю проволоку шины.

- Гидравлическое вытягивание: Гидравлическая система активируется, и высокомощный цилиндр начинает работать, создавая огромную силу тяги, которая заставляет крюк втягиваться.

- Разделение проволоки: Под этим огромным усилием вся стальная проволока ободного кольца полностью вытягивается из резины шины, достигая полного разделения стали и резины.

Весь процесс эффективен и прямолинеен, не требуется предварительная нарезка шины, что делает его важнейшим первым этапом обработки крупногабаритных шин.

Видео работы дебидера шин

Технические характеристики OTR дебидера

| Спецификация | Подробности |

| Модель | 4-метровый OTR дебидер / Машина для вытягивания стальной проволоки |

| Подходящий диаметр шины | 1800 мм – 4000 мм |

| Общая мощность | 22 + 3 кВт |

| Время обработки | Около 2 минут на одну бортовую проволоку |

| Габариты машины (ДШВ) | 7,5 м * 2,2 м * 3,3 м |

| Вес машины | 9500 кг |

Увеличьте ценность переработанных OTR шин

Добавление этой OTR машины для удаления бортовой проволоки в ваш завод по переработке шин — разумный выбор. Это упростит все последующие работы и поможет полностью отделить стальную проволоку и резину из шины. Таким образом, вы получите два чистых материала:

- Качественный стальной лом: Извлеченная проволока ободного кольца — ценное перерабатываемое металло.

- Чистая резина: Ободная шина без обода легче измельчается, что приводит к более чистому резиновому материалу, подходящему для TDF (топливо из шин) или дальнейшей переработки в резиновую крошку и крошку из резины.

Если вы открываете новый цех по переработке OTR шин или хотите модернизировать существующее оборудование по утилизации крупногабаритных шин, наш OTR дебидер — это надежное, мощное и эффективное решение, которое вам нужно.