Shuliy Machinery telah berhasil memasok lini pencucian film LDPE khusus kepada pelanggan di Indonesia. Pelanggan, yang memiliki pabrik pelet plastik sendiri, ingin dapat memproses film LDPE dan mendapatkan serpihan yang bersih dan kering secara menyeluruh. Shuliy Machinery merancang solusi sesuai kebutuhan pelanggan untuk memastikan bahwa pelanggan dapat mencuci dan mengeringkan film LDPE secara efisien.

Latar Belakang dan Kebutuhan Pelanggan

Pelanggan Indonesia adalah seorang praktisi dalam industri daur ulang plastik. Bahan baku yang mereka pasok adalah serpihan LDPE berukuran 1cm, dan pelanggan ingin bahan tersebut dicuci dan dikeringkan secara menyeluruh untuk menjaga kandungan air kurang dari 0,5 persen. Untuk mencapai tujuan ini, mereka ingin membeli lini pencucian film LDPE yang efisien untuk kebutuhan produksi mereka.

Solusi yang Disesuaikan

Melalui komunikasi mendalam dengan pelanggan, Shuliy Machinery menyediakan solusi kustom yang sempurna untuk pelanggan. Sesuai dengan kebutuhan pelanggan, kami memilih mesin pencuci film plastik bekas, mesin pengering serpihan plastik, dan pipa pengering kustom untuk mereka. Ukuran layar pengering juga disesuaikan secara khusus, untuk secara efektif menghindari masalah kebocoran bahan.

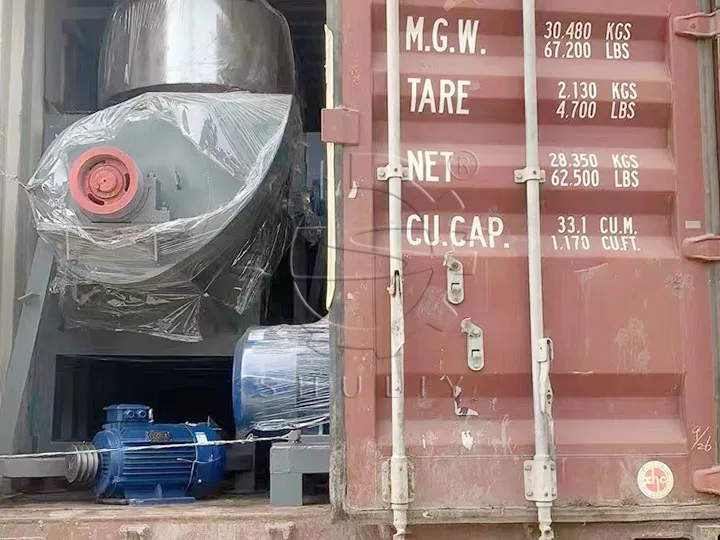

Pengiriman Jalur Pencucian Film LDPE

Shuliy Machinery berkomitmen untuk menyediakan solusi pencucian dan pemrosesan plastik yang efisien dan disesuaikan untuk pelanggan di seluruh dunia. Lini pencucian film LDPE kami mengadopsi teknologi pencucian dan pengeringan canggih, yang dapat memproses film LDPE secara efisien dan memastikan kualitas produk serta kepuasan pelanggan. Jika Anda memiliki kebutuhan pemrosesan pembersihan plastik, jangan ragu untuk menghubungi kami dan kami akan memberikan solusi berkualitas terbaik.