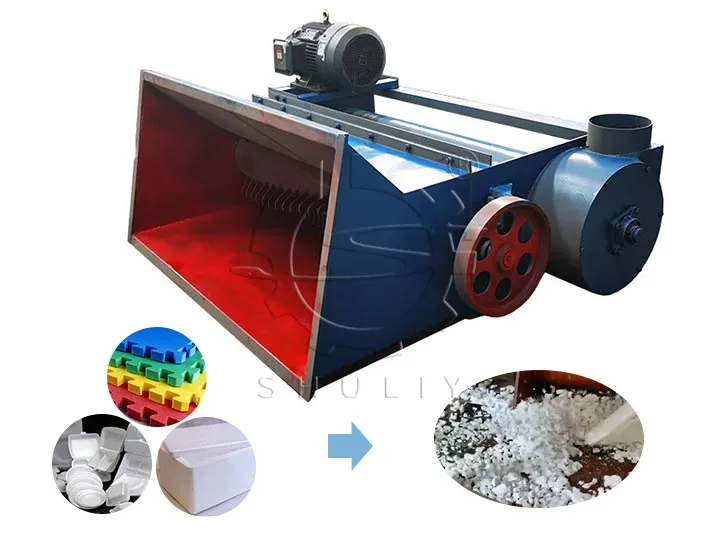

Mesin penghancur busa adalah mesin daur ulang yang dirancang terutama untuk menghancurkan EPS, EPE, dan bahan busa EPP menjadi potongan -potongan kecil untuk daur ulang lebih lanjut, seperti melalui granulasi ekstrusi. Selain itu, shredder busa EPS ini dapat mengurangi volume bahan busa plastik, membuatnya lebih nyaman untuk transportasi. Peralatan ini dapat digunakan dengan granulator busa untuk memproses busa EPS limbah menjadi butiran.

Apa Bahan Baku Penghancur Busa?

Our foam crushing machine is a piece of multi-functional equipment that can effectively crush all kinds of foam materials, including but not limited to disposable lunch boxes, thermal insulation boxes, foam inner liners of electronic products, foam filler materials, pearl cotton, foam board, decorative foams, fruit net covers, etc.

Busa Plastik Hancur

Produk jadi utama dari penghancur busa EPS adalah busa plastik yang dihancurkan. Potongan busa kecil ini dapat dipadatkan menjadi balok oleh alat pemadat busa EPS segera, atau diproses menjadi butiran busa oleh granulator busa EPS.

Fitur Styrofoam Shredder

- Penghancuran efisiensi tinggi: memecah potongan busa besar menjadi yang lebih kecil untuk diproses lebih lanjut.

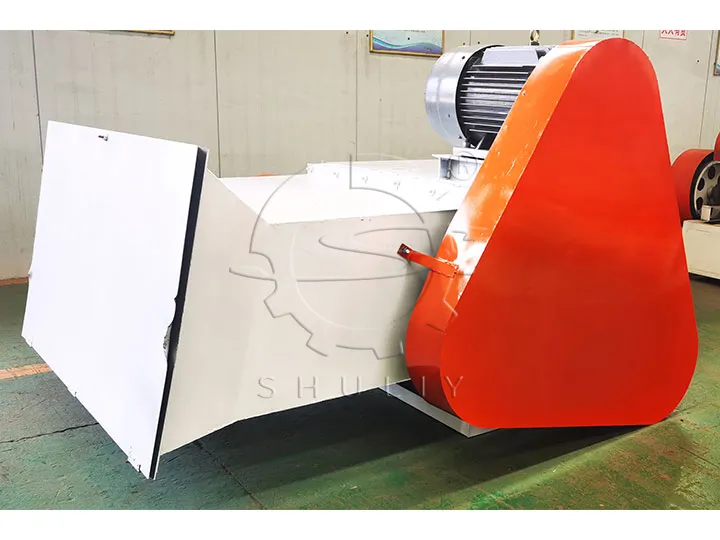

- Desain horizontal: Pemberian makan di permukaan tanah untuk input material yang mudah.

- Aplikasi Serbaguna: Cocok untuk memproses EPS, EPE, XPS, dan bahan busa lainnya.

- Tahan dan dapat diandalkan: Dilengkapi dengan bilah berkualitas tinggi untuk kinerja penghancuran yang lebih baik dan umur layanan yang panjang.

- Efisiensi Daur Ulang yang Ditingkatkan: Mempersiapkan limbah busa untuk peletisasi, kompresi dingin, atau peleburan panas.

- Mudah dioperasikan: Struktur sederhana dengan pemeliharaan yang nyaman.

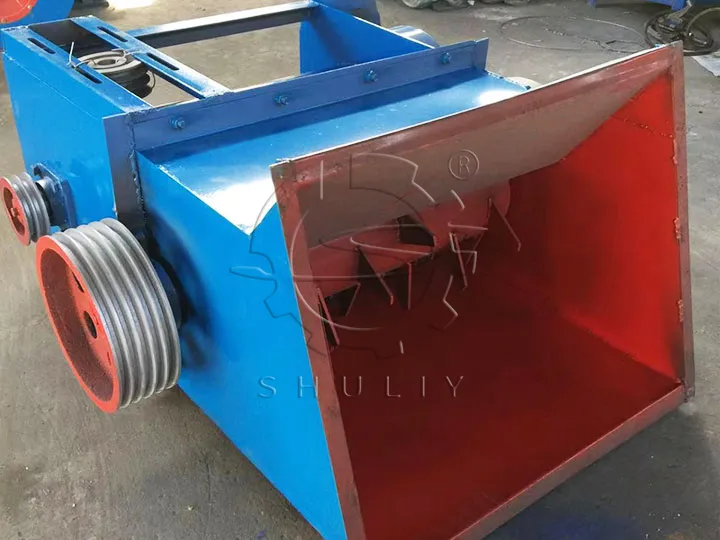

Struktur Dan Proses Mesin Penghancur Busa

- Saluran masuk: Limbah busa dapat dengan mudah dimasukkan ke dalam penghancur busa horizontal melalui saluran masuknya, yang sejajar dengan tanah. Desain ini memungkinkan penyisipan material secara langsung dan mudah, sehingga secara signifikan meningkatkan kenyamanan sekaligus mengurangi kebutuhan tenaga kerja manual.

- Ruang pemotongan: Di ruang pemotongan, pisau tajam memotong bahan busa menjadi potongan-potongan kecil siap untuk langkah selanjutnya.

- Sistem motor dan penggerak: Sistem motor dan penggerak menyediakan daya yang diperlukan untuk memastikan proses pemotongan dan penghancuran yang efisien dan stabil.

- Sistem emisi: Busa yang hancur dibawa ke proses selanjutnya.

Video Kerja Penghancur Busa Plastik

Spesifikasi Penghancur Busa Horisontal

- Kapasitas (KG/Jam): 250-300

- Ukuran keseluruhan (mm): 1250*1290*660

- Ukuran port umpan (mm): 800*600

- Daya (KW): 5,5

- Kapasitas (KG/JAM): 300-350

- Ukuran keseluruhan (mm): 1250*1530*660

- Ukuran port umpan (mm): 1000*600

- Daya (KW): 5,5

- Kapasitas (KG/JAM): 450-500

- Ukuran keseluruhan (mm): 1600*2200*800

- Ukuran port umpan (mm): 1500*800

- Tenaga (KW): 11

Mesin daur ulang busa terkait

Mesin penghancur busa ini biasanya digunakan bersama dengan alat pelet, di mana busa yang dihancurkan diproses lebih lanjut menjadi pelet daur ulang. Selain itu, Anda dapat memilih untuk melelehkan atau memadatkan busa limbah. Kami menawarkan mesin peleburan panas EPS dan pemadat styrofoam untuk memenuhi kebutuhan daur ulang yang berbeda.

Jika Anda ingin mempelajari berbagai pilihan daur ulang, Anda dapat melihatnya di artikel ini: Solusi Daur Ulang Styrofoam: Mengubah Limbah Menjadi Sumber Daya