La máquina enderezadora de barras es un equipo esencial para procesar barras de acero dobladas o de desecho, ampliamente utilizada en plantas de reciclaje de acero y preparación de materiales de construcción. Nuestra empresa ofrece una gama completa de soluciones de enderezado de barras, incluyendo múltiples modelos de máquinas para barras de 6 a 25 mm, puertos de alimentación personalizados, rodillos duraderos y sistemas de doble motor potentes para garantizar un rendimiento de enderezado estable y eficiente. También ofrecemos orientación en la selección de modelos, pruebas en fábrica, suministro de piezas de repuesto y soporte técnico en el extranjero, ayudando a los clientes a poner rápidamente la máquina en operación.

Características clave de la máquina enderezadora de barras de refuerzo

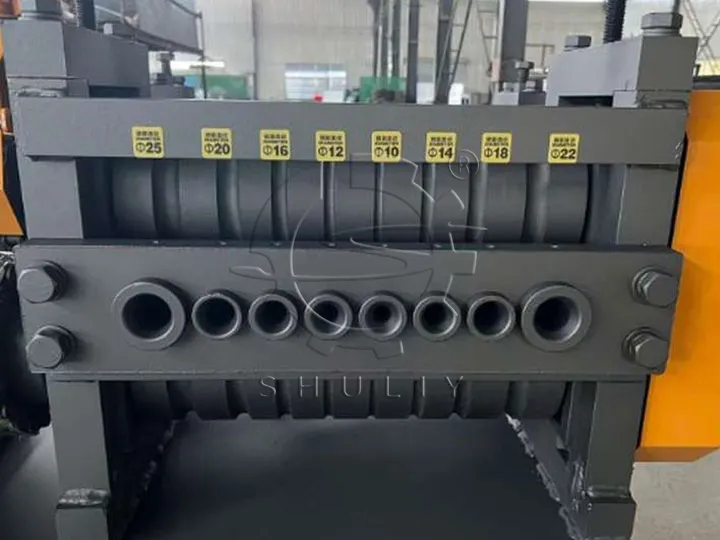

Múltiples orificios de alimentación para diferentes diámetros

Cada modelo cuenta con múltiples orificios de alimentación. Los operadores simplemente seleccionan el orificio que coincide con el diámetro de la barra de acero para una alimentación suave.

Además de los orificios redondos, también están disponibles puertos de alimentación en forma de T para una alimentación más rápida y sencilla.

Rodillos de Enderezado Duraderos y Engrosados

La máquina utiliza rodillos resistentes al desgaste y reforzados, prolongando la vida útil y reduciendo los costos de reemplazo.

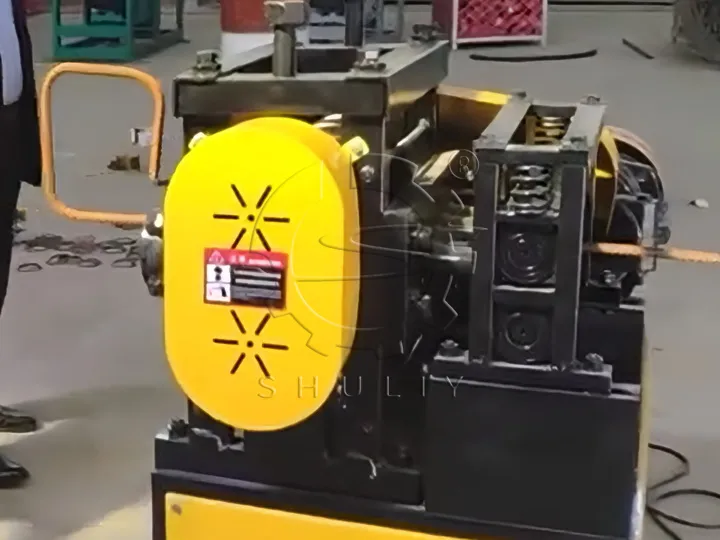

Accionamiento de doble motor estable y de alta eficiencia

La configuración de doble motor proporciona una fuerza de enderezado fuerte, permitiendo una operación continua con una salida estable.

Principio de Funcionamiento de la Máquina Enderezadora de Barras

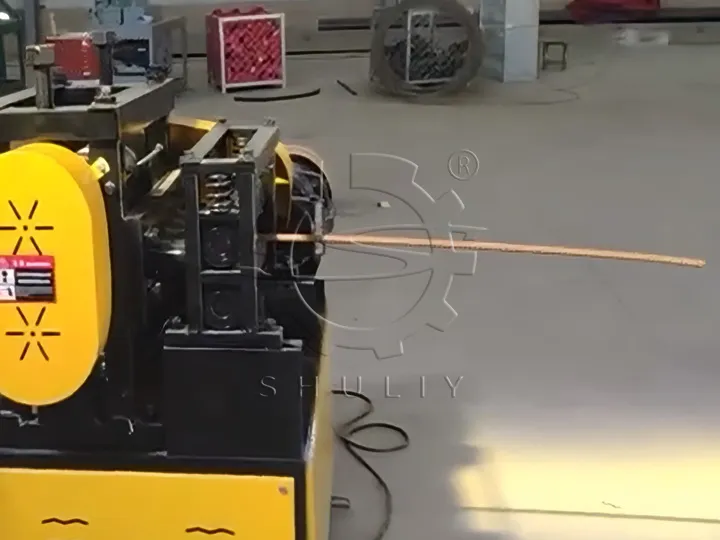

La máquina enderezadora de barras de refuerzo funciona alimentando barras de acero dobladas o de desecho a través de múltiples rodillos de enderezado accionados por un sistema de doble motor y reductor. A medida que la barra pasa por el orificio de alimentación seleccionado, los rodillos giran a alta velocidad, aplicando presión continua para eliminar dobleces y devolver la barra a una condición recta.

Los rodillos reforzados de la máquina aseguran una fuerza estable durante el enderezado, mientras que el orificio de alimentación coincidente o la entrada en T opcional ayudan a guiar diferentes diámetros de manera suave hacia el sistema. Después del enderezado, la barra de acero se entrega automáticamente a la sección de descarga para su colección o procesamiento adicional.

Modelos y especificaciones de máquinas de enderezar varillas

| Modelo | Diámetro de la varilla de enderezado | Agujeros de entrada | Longitud de enderezado | Fuerza de motor | Peso de la máquina | Dimensión de la máquina |

| 6-10 | 6-10 mm | 5 agujeros | 500–2000 mm | 4 kW | 570 kg | 1100×720×1150 mm |

| 6-14 | 6-14 mm | 5 agujeros | 500–2000 mm | 5 kW | 730 kg | 1200×789×1220 mm |

| 8-16 | 8-16 mm | 5 agujeros | 500–2000 mm | 5 kW | 750 kg | 1250×820×1300 mm |

| 14-25 | 14-25 mm | 6 agujeros | 500–2000 mm | 15 kW | 980 kg | 1550×890×1600 mm |

Aplicaciones de la máquina de enderezar barras de acero

- Reciclaje de varillas de acero de desecho

- Reutilización de barras de acero en obras de construcción

- Talleres de procesamiento de acero

- Enderezado de barras de acero de chatarra

- Instalaciones de reciclaje de metal

Esta máquina de enderezar varillas ayuda a restaurar varillas dobladas o descartadas, mejorando la utilización del material y reduciendo los residuos.

¿Por qué elegir nuestra máquina de enderezar varillas?

- Admite un amplio rango de enderezado (6–25 mm)

- Accionamiento de doble motor potente y rendimiento suave

- Múltiples agujeros de alimentación entrada en T opcional

- Rodillos duraderos para una larga vida útil

- Operación estable con baja tasa de fallos

Solicitar presupuesto para la máquina de enderezar varillas

Si necesita una máquina de enderezado de varillas confiable para procesar y reciclar barras de acero, no dude en contactarnos. Nuestro equipo recomendará el modelo adecuado según el diámetro de su barra, los requisitos de producción y su presupuesto.

Equipos relacionados para el procesamiento de varillas

Para apoyar todas las necesidades de procesamiento de barras de acero, también ofrecemos máquinas relacionadas para el procesamiento de varillas. Estas incluyen la máquina de hacer anillos de varillas para formar anillos circulares, la máquina de doblar estribos de varillas para dar forma a estribos de construcción, y la máquina CNC de doblado de tubos para doblar tubos o tuberías con precisión. Nuestro equipo satisface una amplia gama de requisitos de procesamiento. Si necesita nuestros servicios, no dude en contactarnos.