La máquina de limpieza con hielo seco es una solución de limpieza industrial eficiente y no abrasiva diseñada para aplicaciones donde la protección de superficies, la eficiencia de limpieza y las consideraciones ambientales son importantes. Desde nuestra experiencia como proveedor de equipos, los clientes generalmente se centran no solo en los resultados de limpieza, sino también en si la máquina se ajusta a sus condiciones operativas reales y a sus necesidades de uso a largo plazo.

Qué es una máquina de limpieza por chorro de hielo seco

Una máquina de limpieza por chorro de hielo seco utiliza pellets de dióxido de carbono sólido como medio de limpieza. Durante la operación, los pellets de hielo seco son acelerados por aire comprimido y dirigidos hacia la superficie objetivo. El efecto de limpieza proviene de una combinación de impacto cinético, choque térmico y sublimación instantánea del hielo seco.

A diferencia de los métodos de limpieza convencionales, este proceso no genera residuos secundarios como aguas residuales o residuos químicos. Por esta razón, se usa ampliamente en industrias que requieren procesos de mantenimiento limpios, secos y eficientes.

Qué hace una máquina de limpieza con hielo seco

Basándose en la retroalimentación de los clientes y escenarios de aplicación reales, las máquinas de chorro de hielo seco se utilizan comúnmente para:

- Eliminación de aceite, grasa y residuos de moldes y piezas mecánicas

- Limpieza de equipos de producción sin desmontaje

- Mantenimiento de componentes eléctricos y superficies sensibles

- Eliminación de acumulaciones de carbono, adhesivos, resinas y contaminantes ligeros

En estas aplicaciones, una máquina de limpieza con hielo seco permite una limpieza efectiva mientras minimiza el riesgo de daño a la superficie y reduce el tiempo de inactividad.

Principales ventajas de nuestro chorro de hielo seco

Configuración personalizable: La configuración de la máquina y los accesorios opcionales pueden personalizarse según diferentes materiales de limpieza, condiciones de superficie y requisitos de aplicación.

Varios modelos disponibles: Hay varios modelos de máquinas para adaptarse a diferentes cargas de trabajo de limpieza, frecuencias de operación y condiciones de suministro de aire.

Entrega rápida en stock: Los modelos estándar se mantienen en stock, permitiendo un envío rápido y plazos de entrega más cortos tras la confirmación del pedido.

Diseño industrial estable: Diseñado para un rendimiento constante en entornos industriales, adecuado para operaciones a largo plazo y continuas.

Operación sencilla y fácil mantenimiento: Controles fáciles de usar con parámetros ajustables que hacen que la operación diaria y el mantenimiento rutinario sean eficientes.

Compatible con máquinas de pellets de hielo seco: Puede usarse junto con fabricantes de pellets de hielo seco para formar una solución completa de producción y limpieza con hielo seco.

Soporte de un solo proveedor: Se proporciona soporte técnico desde la selección de la máquina hasta la configuración del sistema, ayudando a garantizar que el equipo se adapte a las necesidades reales de la aplicación.

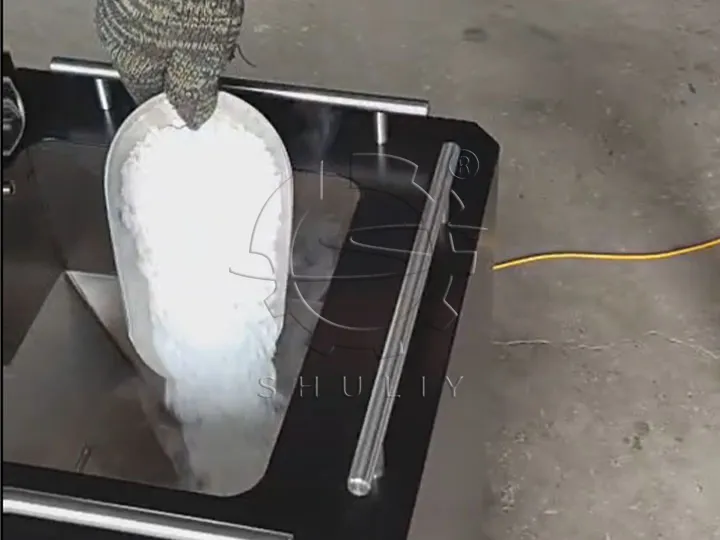

Video de trabajo de la máquina de limpieza con hielo seco

Trabajando con una Máquina de Pellets de Hielo Seco

Para clientes que planifican un sistema completo de aplicación de hielo seco, la máquina de limpieza con hielo seco puede usarse junto con una máquina de pellets de hielo seco. La máquina de pellets produce pellets de hielo seco en el sitio o de forma centralizada, que luego se alimentan directamente al sistema de chorro.

Esta combinación ayuda a mejorar la eficiencia operativa y permite un mejor control sobre los costos de consumo de hielo seco. También podemos ayudar a seleccionar una capacidad de producción de pellets adecuada según la frecuencia de limpieza y la carga de trabajo.

Modelos de equipos de chorro de hielo seco

Actualmente ofrecemos dos modelos populares: SL-40 y SL-80. Ambos modelos son máquinas de limpieza con hielo seco de un solo tubo y están diseñados para diferentes necesidades de limpieza y frecuencias de uso.

El SL-40 tiene una capacidad de hielo seco de 25 kg, adecuado para tareas de limpieza pequeñas a medianas. Cuenta con un consumo ajustable de hielo seco, una estructura compacta y es fácil de mantener y operar en el sitio. El SL-80 tiene una capacidad de hielo seco de 36,4 kg, adecuado para cargas de limpieza mayores o una mayor frecuencia de limpieza industrial. Ofrece una mayor capacidad de almacenamiento de hielo seco y un margen operativo superior.

Ambos modelos soportan un consumo ajustable de hielo seco y un rango de presión de aire, permitiendo a los clientes ajustar los parámetros según el objetivo de limpieza y las condiciones del sitio, cumpliendo con diferentes requisitos de trabajo.

Cómo apoyamos tu decisión de compra

En la práctica, no recomendamos un solo modelo sin entender su aplicación. En cambio, evaluamos factores como los objetivos de limpieza, la frecuencia de operación, el suministro de aire disponible y si se requiere una máquina de pellets de hielo seco.

Como proveedor, nuestro objetivo es ayudarte a seleccionar una solución de limpieza con hielo seco que sea práctica, confiable y adecuada para operaciones a largo plazo, no solo una máquina que cumpla con las especificaciones básicas.

Si estás considerando si una máquina de limpieza con hielo seco se ajusta a tus requisitos de producción o mantenimiento, estamos listos para apoyarte con análisis de aplicaciones, selección de equipos y soluciones completas de sistemas de hielo seco. No dudes en contactarnos para obtener asesoramiento detallado de configuración e información técnica.