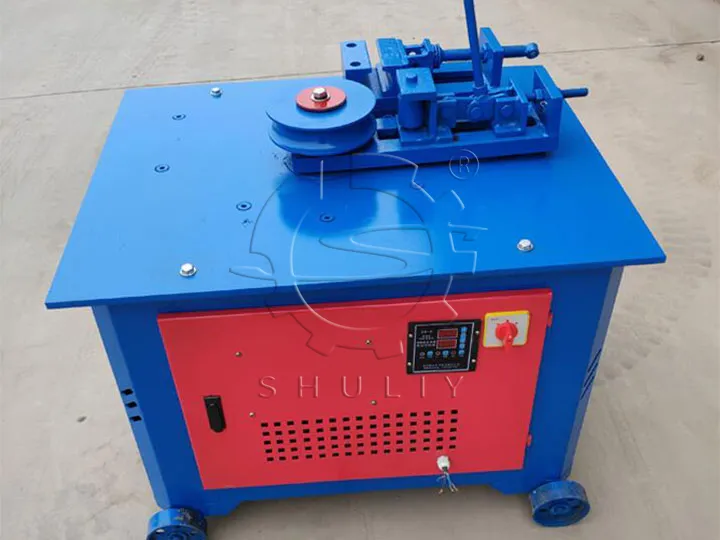

Una máquina de doblado de tubos CNC es una máquina automática de conformado de tubos que utiliza un sistema de control CNC o hidráulico para controlar con precisión los ángulos y las trayectorias de doblado. Está diseñada para doblar con alta precisión diversos tubos y tuberías de metal. Con un rendimiento estable y un alto nivel de automatización, esta máquina cumple con los estrictos requisitos de las industrias modernas en cuanto a consistencia, eficiencia y fiabilidad en la producción.

Aplicaciones de la máquina de doblado de tubos CNC

Los dobladoras de tubos CNC se utilizan ampliamente en industrias que requieren accesorios de tubería precisos y duraderos, incluyendo:

- Sistemas de escape y marcos para automóviles y motocicletas

- Sistemas de tuberías aeroespaciales y de construcción naval

- Industria petroquímica, eléctrica y de gas natural

- Calderas, recipientes a presión y tuberías industriales

- Equipamiento de fitness, artículos deportivos y mobiliario de metal

- Proyectos de aire acondicionado, refrigeración y decoración en acero inoxidable

La máquina es adecuada para tubos redondos, tubos de acero, acero inoxidable, aluminio y ciertos tubos de forma especial.

Video de funcionamiento del doblador de tubos CNC

Ventajas clave de la máquina de doblado de tubos CNC

Alta precisión de doblado y conformado estable

Equipado con un sistema de control CNC o hidráulico, el rango de ángulo de doblado alcanza de 0 a 180 grados, asegurando alta repetibilidad y reduciendo la deformación y el desperdicio del tubo.

Alto nivel de automatización

Los procesos de alimentación y doblado se completan automáticamente, reduciendo la mano de obra y mejorando la eficiencia de producción. Ideal para producción en lotes y operación a largo plazo.

Múltiples modelos para diferentes tamaños de tubos

Una amplia gama de modelos disponibles, cubriendo diámetros de tubo desde 10 mm hasta 100 mm, con diferentes capacidades de grosor de pared para satisfacer diversos requisitos de procesamiento.

Estructura compacta y fácil mantenimiento

La máquina presenta un diseño compacto, huella pequeña, componentes duraderos y bajos costos de mantenimiento.

Modelos y parámetros técnicos de máquinas de doblado de tubos CNC

Modelos de dobladoras de tubos CNC eléctricas

| Modelo | Rango de doblado | Rango de ángulo | Velocidad principal | Grosor de pared | Fuerza de motor | Peso |

| Modelo 38 | 10–24 mm | 0–180° | 20 rpm | 1–3 mm | 3 kW | 230 kg |

| 20–51 mm | 1–4 mm | 0–180° | 20 rpm | 260 kg | 3 kW | 30–76 mm |

| 16 rpm | 1–5 mm | 0–180° | 290 kg | 40–100 mm | 4 kW | 2–6 mm |

| 360 kg | Velocidad de desplazamiento | 0–180° | 290 kg | Modelo-5 Hidráulico CNC | 5,5 kW | Tubo redondo 10–50 mm / Barra de acero 4–28 mm |

Modelos de máquinas de doblado de tubos hidráulicas CNC

| Modelo | Capacidad de procesamiento | 12 m/min | Fuerza de motor | Peso de la máquina |

| 700 kg | Modelo-9 Hidráulico CNC | Tubo redondo 10–60 mm / Barra de acero 4–32 mm | 3 kW | 3.8 kW |

| 900 kg | Modelo-11 Hidráulico CNC | Tubo redondo 10–60 mm / Barra de acero 4–32 mm | Tubo redondo 10–60 mm / Barra de acero 4–36 mm | 1050 kg |

| Dobladora de tubos CNC | Máquina de doblado CNC para tubos | Tubo redondo 10–60 mm / Barra de acero 4–32 mm | 5,5 kW | Al seleccionar una máquina de doblado de tubos CNC, considere los siguientes factores: |

Cómo elegir la máquina de doblado de tubos CNC adecuada

Requisitos de eficiencia de producción (velocidad y rendimiento)

- Suministro de energía y espacio de instalación

- El precio de una máquina de doblado de tubos CNC varía según la capacidad de doblado, tipo de accionamiento (eléctrico o hidráulico) y configuración. Elegir el modelo adecuado según sus necesidades de producción puede ayudar a reducir los costos de fabricación y garantizar una calidad de producto constante.

- Si busca una máquina de doblado de tubos CNC estable, precisa y duradera, contáctenos para más información. Recomendaremos un modelo adecuado según las especificaciones de su tubo, industria de aplicación y requisitos de producción, y proporcionaremos parámetros técnicos detallados y una cotización competitiva.

- Al combinar máquinas de doblado de tubos CNC con estas máquinas de procesamiento de barras de refuerzo, los clientes pueden construir una línea de fabricación de metales más completa y eficiente, adecuada para proyectos de construcción, componentes prefabricados y aplicaciones de fabricación industrial.

- Servicio postventa y soporte técnico.

Guía de precios y compra de máquinas de doblado de tubos CNC

El precio de una máquina de doblado de tubos CNC varía según la capacidad de doblado, el tipo de accionamiento (eléctrico o hidráulico) y la configuración. Elegir el modelo correcto según sus necesidades de producción reales puede ayudar a reducir los costos generales de fabricación mientras se garantiza una calidad de producto constante.

Si busca una máquina de doblado de tubos CNC estable, precisa y duradera, póngase en contacto con nosotros para obtener más información. Recomendaremos un modelo adecuado según las especificaciones de su tubo, la industria de aplicación y los requisitos de producción, y proporcionaremos parámetros técnicos detallados y una cotización competitiva.

Máquinas relacionadas para el procesamiento de barras de refuerzo y soluciones completas de conformado de metales

Además de las máquinas de doblado de tubos CNC, también ofrecemos una gama completa de equipos de procesamiento de barras de refuerzo para satisfacer diferentes necesidades de conformado de metales y construcción. Para enderezar barras de acero crudas antes de doblar, se suele usar una máquina de enderezado de barras de acero para mejorar la precisión y eficiencia del procesamiento. Cuando se requieren formas circulares o en espiral, una máquina de fabricación de anillos de barras de refuerzo puede formar automáticamente las barras en anillos consistentes. Para doblado de ángulos y conformado de formas, una máquina de doblado de barras de refuerzo es ideal para producir estribos, marcos y ángulos de doblado personalizados.

Al combinar máquinas de doblado de tubos CNC con estas máquinas de procesamiento de varillas, los clientes pueden construir una línea de fabricación de metales más completa y eficiente, adecuada para proyectos de construcción, componentes prefabricados y aplicaciones de fabricación industrial.