Nuestra máquina trituradora de chatarra es la piedra angular de una operación moderna y rentable de reciclaje de metales, diseñada específicamente para reducir eficientemente el volumen de varias chatarra metálica. En nuestra empresa, no solo vendemos máquinas; ofrecemos soluciones robustas de alto torque adaptadas a tus necesidades únicas. Nos enfocamos en durabilidad, rendimiento y personalización completa, asegurando que recibas una máquina que maximice tu eficiencia de reciclaje y retorno de inversión.

¿Qué materiales puede procesar nuestra trituradora de doble eje?

Nuestras trituradoras de chatarra son increíblemente versátiles. Aunque sobresalen en el procesamiento de metales, su diseño potente les permite manejar una amplia variedad de otros residuos.

Metales

- Autos chatarra, vehículos fuera de uso (ELVs)

- Barriles de acero, cubos de pintura y barriles de aceite

- Perfiles de aluminio, puertas y ventanas

- Bloques de motor y fundiciones de chatarra

- Chatarra de metal ligero, chapa metálica

- Cables de cobre, cables de aluminio y radiadores

- Latas de aluminio y chatarra metálica en fardos

Plásticos

- Botellas de plástico (PET), tambores de plástico, tanques IBC

- Cestas de plástico, cajas y palets

- Bolsas tejidas, bolsas jumbo y película agrícola

Neumáticos y caucho

Neumáticos de coche, neumáticos de camión (deben ser desarmados en algunos modelos)

Madera

Palets de madera, madera de construcción, raíces de árboles

Ventajas clave de nuestra trituradora de chatarra de doble eje

Nos enfocamos en beneficios tangibles que impactan directamente en tus operaciones.

- Procesamiento versátil de materiales: Diseñado para manejar no solo metal, sino una amplia gama de materiales duros, convirtiéndolo en una inversión multifuncional para tu patio de reciclaje.

- Soluciones totalmente personalizables: Personalizamos el diseño de las cuchillas, el grosor, el número de garras y las dimensiones de la máquina para adaptarnos perfectamente a tu material y requisitos de salida.

- Amplia gama de modelos: Desde trituradoras pequeñas hasta sistemas de gran capacidad, ofrecemos una línea completa de productos para diferentes demandas de rendimiento y presupuestos.

- Opciones de energía flexibles (eléctrica o diésel): Para sitios de trabajo sin una fuente de energía trifásica estable, podemos equipar tu máquina trituradora de chatarra con un potente motor diésel para total movilidad y libertad operativa.

- Sistema de control PLC inteligente: La máquina está equipada con un sistema PLC que proporciona protección automática contra sobrecargas. Si la máquina detecta un atasco, los ejes invertirán automáticamente para despejar el material, y luego reanudarán el triturado, protegiendo el motor y la caja de cambios.

Cómo funciona: trituración de precisión y control de tamaño

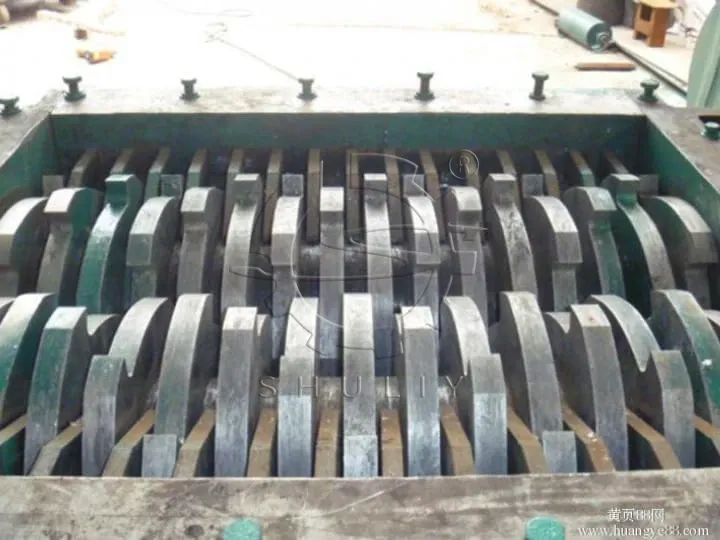

Nuestra trituradora de chatarra de doble eje funciona bajo el principio de cizalladura y desgarro. El material se alimenta por la tolva y es agarrado por los ejes de rotación opuesta equipados con cuchillas afiladas y entrelazadas. La alta torsión y baja velocidad de los ejes permiten que la máquina rasgue y corte el material en piezas más pequeñas.

Para clientes que requieren un tamaño de salida uniforme, podemos instalar una pantalla de tamaño personalizado (tamiz circular). El material triturado al tamaño deseado pasa a través de la pantalla, mientras que las piezas sobredimensionadas son llevadas de regreso a la parte superior por las cuchillas para un mayor triturado hasta que sean lo suficientemente pequeñas para pasar. El tamaño final del material es ajustable y puede controlarse con precisión cambiando la configuración de las cuchillas y el tamaño de la malla de la pantalla.

Mira nuestra trituradora de chatarra en acción

Ve por ti mismo cómo nuestra máquina trituradora de chatarra procesa sin esfuerzo chatarra pesada.

Preguntas frecuentes (FAQ) de la trituradora de doble eje

Q1: ¿Cuál es el tamaño final de salida del material triturado?

A: El tamaño de salida es completamente personalizable. Configuraremos la máquina según tus requisitos específicos.

Q2: ¿Puedes proporcionar una solución para mi tipo específico de chatarra?

A: Absolutamente. Te animamos a enviarnos una muestra de tu material. Ofrecemos pruebas de material gratuitas para determinar la mejor configuración de máquina para ti.

Q3: ¿Qué hay del servicio postventa y las piezas de repuesto?

A: Proporcionamos soporte postventa integral, incluyendo orientación en la instalación y capacitación operativa. Piezas de repuesto clave como cuchillas están disponibles en nuestro stock para minimizar tu tiempo de inactividad.

Aplicación en la línea de reciclaje de aluminio con rotura térmica

Esta máquina trituradora de chatarra metálica también puede servir como equipo de trituración primaria en las líneas de reciclaje de aluminio con rotura térmica. Reduce los perfiles de aluminio con rotura térmica mediante desgarro y cizalladura, ayudando a liberar el aluminio de las tiras de aislamiento de plástico y preparar el material para la trituración secundaria y la separación por corrientes de Foucault.

Existen diferentes modelos para adaptarse a varias capacidades y condiciones del material.

Contáctenos para seleccionar un modelo de trituradora adecuado para su proyecto de reciclaje de aluminio con rotura térmica.

Amplía tus capacidades de procesamiento de metales

Mientras que una máquina trituradora de chatarra metálica es un componente central para procesar una amplia gama de materiales, también ofrecemos otros equipos especializados para manejar diferentes aspectos del reciclaje de metales. La combinación de estas máquinas puede ayudarte a crear una operación más completa y eficiente.

Compresor de chatarra: Nuestrocompresor de chatarraes perfecto para comprimir materiales sueltos, incluyendo chatarra triturada o metales ligeros, en fardos densos y fáciles de manejar. Este proceso reduce drásticamente los costos de almacenamiento y transporte, haciendo que tu producto final sea más atractivo para acerías y fundiciones.

Cizalla de pórtico: Para chatarra pesada o de tamaño excesivo que supera la capacidad de alimentación de la trituradora, nuestra robustacizalla de pórticoes la solución ideal. Corta eficientemente grandes elementos como vigas en I, tuberías y placas pesadas en tamaños manejables, preparándolos para la trituradora o para su venta directa.

¡Obtén tu cotización personalizada para una trituradora de chatarra hoy mismo!

¿Listo para mejorar tus capacidades de reciclaje y aumentar tus beneficios? Nuestro equipo de expertos está aquí para ayudarte a seleccionar la máquina trituradora industrial perfecta.

Contáctanos hoy para una cotización sin compromiso y una consulta gratuita. Simplemente completa el formulario con tus requisitos, o para una respuesta más rápida, añádenos en WhatsApp. Te proporcionaremos una propuesta técnica detallada, precios y asesoramiento experto para ayudarte a tomar la mejor decisión para tu negocio.