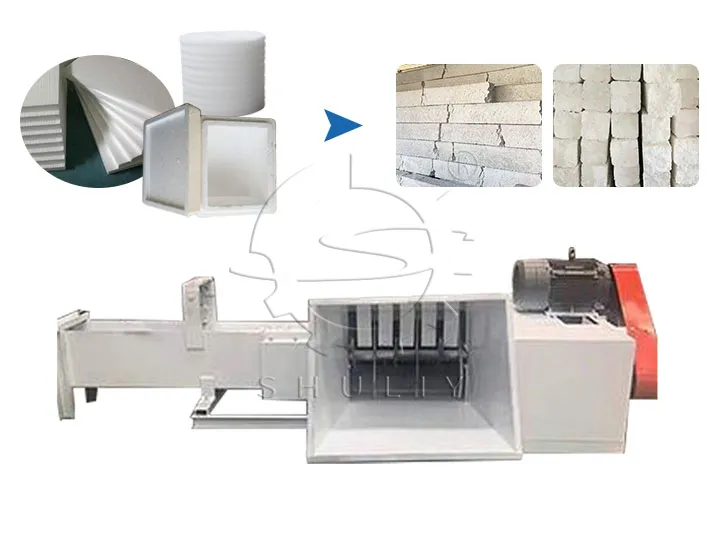

Kompa EPS foam horizontal adalah sama dengan kompa EPS foam vertikal. Ini digunakan untuk memadatkan bahan foam menjadi blok EPS yang dipadatkan dengan rapat. EPS foam biasanya memiliki kepadatan rendah dan memakan banyak ruang. Dengan menggunakan mesin kompa foam, EPS foam dapat dipadatkan menjadi bentuk yang lebih kecil dan kompak, sehingga mengurangi ukurannya dan menghemat ruang untuk penyimpanan dan transportasi.

Apa itu Pemadat Busa EPS Horizontal?

Pemadat busa EPS adalah peralatan yang dirancang untuk memproses dan menangani bahan busa EPS. Bahan busa EPS biasanya ditemukan dalam bentuk balok busa, papan busa, atau bola busa yang digunakan dalam berbagai aplikasi seperti pengemasan, insulasi bangunan, dan dekorasi artistik.

Fungsi utama pemadat busa EPS horizontal adalah untuk mengompres bahan busa EPS tersebut menjadi balok yang lebih padat. Proses pemadatan ini dirancang untuk mengurangi volume busa EPS dan mengurangi biaya penyimpanan dan transportasi.

Mengapa Membutuhkan Mesin Foam Compactor?

- Mengurangi Volume: Mesin pemadat busa mengurangi volume busa dan menghemat ruang penyimpanan dan transportasi.

- Peningkatan Kekuatan Material: Proses pemadatan dapat meningkatkan kepadatan dan kekuatan busa EPS, sehingga lebih cocok untuk aplikasi tertentu.

- Penghematan Biaya: Dengan mengurangi volume busa EPS, pemadatan dapat menurunkan biaya penyimpanan dan transportasi.

Limbah Busa EPS

Aplikasi

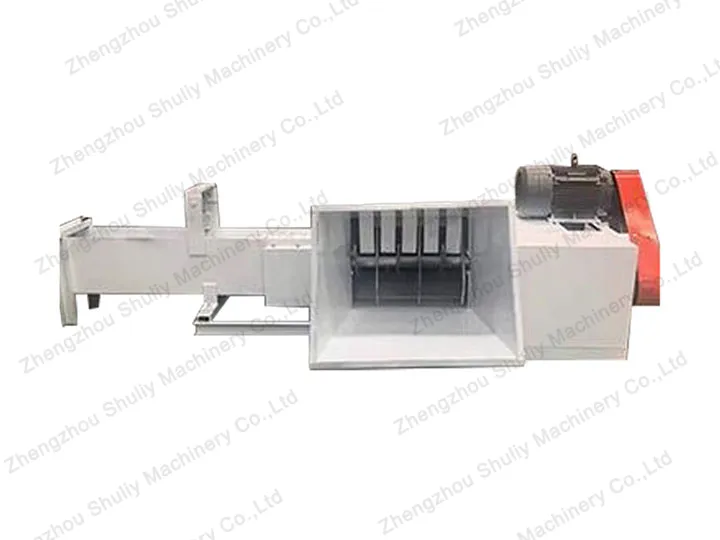

Parameter Pemadat Busa EPS Horizontal

Ketik 300

- Kapasitas (KG/Jam): 175

- Tenaga (KW): 15

- Ukuran mesin (mm): 3000*1700*900

- Ukuran saluran masuk (mm): 830*760

Ketik 400

- Kapasitas (KG/Jam): 300

- Daya (KW): 22

- Ukuran mesin (mm): 4600*2800*1200

- Ukuran saluran masuk (mm): 870*860

Kami juga menawarkan jenis pemadat busa lainnya, jadi jika Anda mencari cara efektif untuk mendaur ulang busa EPS, pertimbangkan untuk membeli pemadat busa EPS.