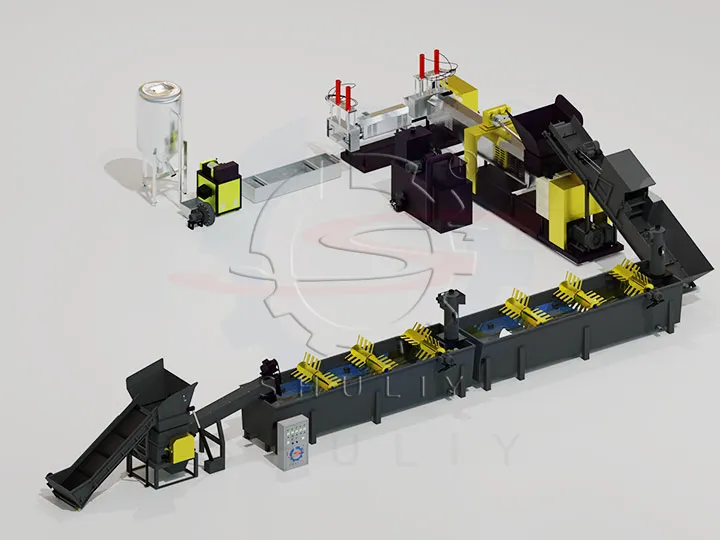

Garis granulasi tas anyaman adalah fasilitas pemrosesan tas anyaman plastik bekas atau bekas, yang dirancang untuk mengubah limbah ini menjadi pelet atau butiran plastik daur ulang. Jalur tersebut biasanya mencakup serangkaian langkah proses untuk memastikan daur ulang dan penggunaan kembali tas anyaman bekas dan limbah yang efisien. Pada artikel ini, kami akan memberikan pengenalan mendalam tentang karakteristik proses lini daur ulang tas anyaman PP dan berbagai keunggulan merek Shuliy Machinery kami di bidang ini.

Proses Garis Granulasi Tas Anyaman

Proses jalur daur ulang tas anyaman PP telah dirancang dengan cermat untuk mencakup langkah-langkah berikut:

- Pengumpulan: Limbah tas anyaman PP dikumpulkan dari berbagai sumber.

- Menghancurkan: Gunakan profesional penghancur kantong plastik untuk menghancurkan limbah tas anyaman PP secara efisien.

- Pencucian dan pengeringan: Plastik yang dihancurkan dimasukkan ke dalam tangki pencuci plastik untuk menghilangkan kotoran dan kotoran yang menempel pada permukaan plastik. Kemudian mesin dewatering film plastik untuk mengeringkannya.

- Granulasi: Menggunakan a granulator daur ulang tas anyaman, plastik yang sudah dibersihkan diolah lebih lanjut menjadi pelet plastik yang dapat digunakan untuk produk baru.

- Pendinginan dan pemotongan: Setelah granulasi plastik selesai, potongan plastik perlu didinginkan dalam tangki pendingin dan kemudian dipotong menjadi butiran dengan ukuran yang diperlukan dengan mesin pemotong butiran plastik.

Keuntungan Jalur Daur Ulang Tas Anyaman PP

Kapasitas tinggi: jalur granulasi kantong anyaman dari Shuliy Machinery memiliki kapasitas yang sangat baik untuk memenuhi kebutuhan daur ulang plastik skala besar dan memastikan produksi yang efisien.

Pelet plastik berkualitas tinggi: Melalui proses yang disempurnakan, Shuliy Machinery memproduksi pelet plastik berkualitas tinggi yang memenuhi standar produksi yang tinggi.

Solusi individual: Kami menawarkan solusi individual, lini produksi yang dibuat khusus untuk memenuhi kebutuhan spesifik berbagai industri semaksimal mungkin.

Layanan purna jual: Shuliy Machinery berkomitmen untuk menyediakan berbagai layanan purna jual untuk memastikan bahwa pelanggan selalu mendapatkan dukungan teknis dan pemeliharaan tepat waktu dalam operasi produksi.