Mesin pelet plastik sebagai peralatan utama daur ulang plastik perlu dilakukan secara terpisah ketika menangani bahan lunak dan keras. Mengapa bahan lunak dan bahan keras tidak dapat dicampur dan dijadikan pelet? Mari kita telusuri masalah ini bersama-sama secara mendalam.

Perbedaan Bahan Lunak Dan Bahan Keras

Ada perbedaan yang jelas antara bahan lunak dan keras dalam hal sifat fisik dan kimia:

- Karakteristik bahan lunak: seperti polietilen (PE) dan plastik lunak lainnya biasanya lunak, lentur, meregang, dll., Struktur molekulnya longgar, dan mudah terpengaruh oleh panas dan pelunakan.

- Ciri-ciri bahan keras: seperti polipropilen (PP) dan plastik keras lainnya biasanya mempunyai ciri kekerasan tinggi, kuat tarik kuat, tidak mudah berubah bentuk, dll, serta struktur molekulnya padat dan titik lelehnya tinggi.

Tantangan dalam Pengoperasian Mesin Pelet Plastik

Selama proses pembuatan pelet, perbedaan antara bahan lunak dan keras dapat menimbulkan masalah berikut:

- Perbedaan titik leleh: Titik leleh bahan lunak dan bahan keras berbeda secara signifikan, sehingga sulit untuk menyeimbangkan suhu pelet untuk keduanya.

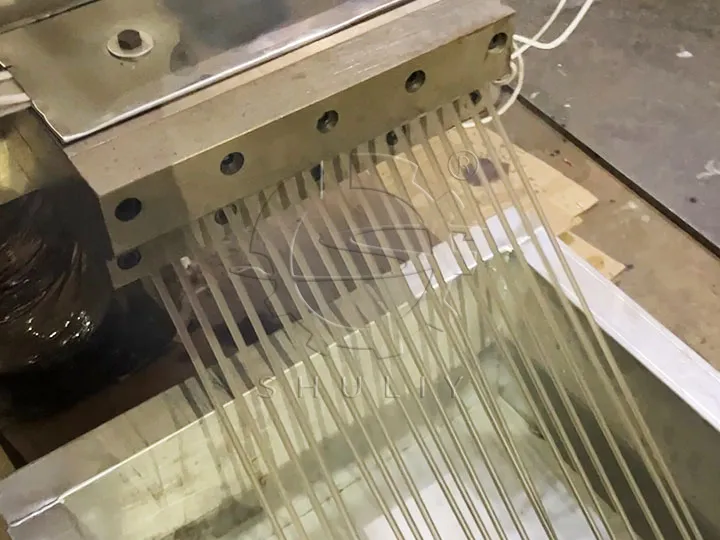

- Perbedaan fluiditas: Bahan lunak dan bahan keras memiliki fluiditas yang berbeda, yang dapat menyebabkan bahan tidak rata dan fluiditas buruk saat pencampuran dan pelet dalam satu wadah. mesin pelet plastik.

- Kesulitan Pencetakan: Persyaratan pencetakan untuk bahan lunak dan keras juga berbeda dan pencampuran serta pembuatan pelet dapat menyebabkan kesulitan pencetakan atau penurunan kualitas produk jadi.

Ringkasan: Granulasi Terpisah Untuk Memastikan Kualitas Produk

Perbedaan antara bahan lunak dan keras adalah tidak dapat diproses secara bersamaan dalam proses pelet. Oleh karena itu, untuk memastikan kualitas produk dan efisiensi produksi, bahan lunak dan keras harus dibuat pelet secara terpisah dan diolah secara terpisah sesuai dengan karakteristik dan persyaratannya. Hal ini akan memastikan bahwa produk pelet akhir memiliki kualitas yang stabil dan efek pencetakan yang baik, sehingga memberikan lebih banyak manfaat bagi pelanggan.