Saat menggunakan granulator daur ulang plastik, spesifikasi pengoperasian berikut adalah kunci untuk memastikan produksi yang aman, efisien, dan meningkatkan kualitas pelet plastik. Berikut beberapa saran dan spesifikasi cara mengoperasikan mesin pelet daur ulang plastik dengan benar.

Inspeksi dan Pemeliharaan Granulator Daur Ulang Plastik

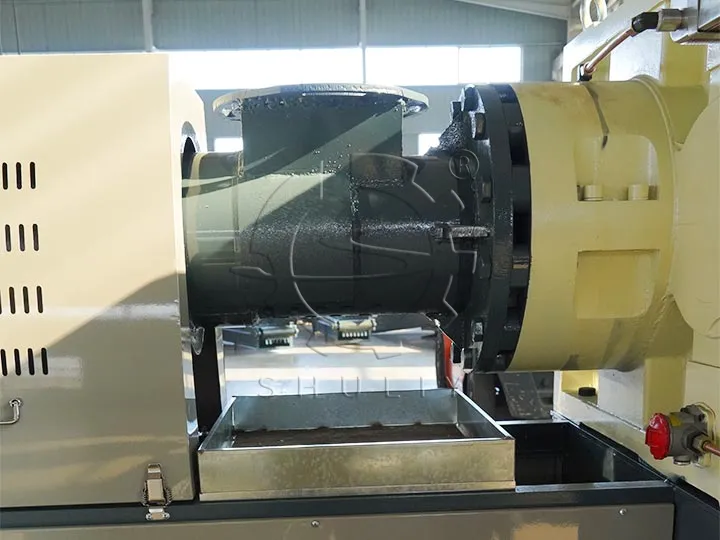

- Pemeriksaan peralatan secara berkala: Sebelum digunakan, kondisi peralatan harus diperiksa untuk memastikan semuanya baik-baik saja, termasuk sambungan listrik, alat pemanas, sekrup, cetakan, dll.

- Perawatan rutin: Lakukan perawatan peralatan secara berkala, seperti pembersihan, pelumasan, dan penggantian suku cadang yang aus, sesuai dengan jadwal perawatan yang disediakan oleh produsen granulator.

Persiapan Bahan Baku

- Penyimpanan bahan mentah yang benar: Bahan mentah harus disimpan di tempat yang kering dan berventilasi untuk menghindari kelembapan dan kontaminasi oleh kotoran.

- Pakan seragam: Saat menambahkan bahan mentah, pastikan pakan seragam dan cegah penyumbatan untuk menjamin kualitas dan konsistensi pelet.

Langkah Pengoperasian Mesin Pelet Daur Ulang Plastik

- Persiapan permulaan: Sebelum memulai granulator daur ulang plastik, pastikan semua peralatan telah diperiksa dan siap digunakan, termasuk membersihkan cetakan dan sekrup.

- Penyesuaian suhu: Tergantung pada bahan baku yang digunakan, suhu elemen pemanas disesuaikan untuk memastikan bahwa plastik diproses pada suhu yang sesuai.

- Pengoperasian permulaan: Nyalakan mesin dan secara bertahap tingkatkan kecepatan kerja mesin pelet daur ulang plastik untuk memastikan ekstrusi lelehan plastik yang seragam.

- Pemantauan operasi: Selama pengoperasian, pantau terus status pengoperasian peralatan untuk memastikan semuanya beres, berikan perhatian khusus pada fluktuasi suhu dan tekanan.

- Prosedur penghentian: Sebelum menghentikan granulator daur ulang plastik, kurangi kecepatan ekstruder, lalu matikan mesin dan tunggu hingga benar-benar dingin sebelum membersihkannya.

Pembersihan dan Pemeliharaan

- Pembersihan Reguler: Setelah digunakan, bersihkan peralatan tepat waktu, termasuk cetakan, sekrup, tong, dll., untuk menghindari residu yang mempengaruhi produksi berikutnya.

- Perawatan tepat waktu: Perawatan peralatan secara teratur dan penggantian suku cadang yang aus memastikan kinerja peralatan.