Im Produktionsprozess von Eierkartons enthalten die geformten nassen Produkte über 70 % Feuchtigkeit und müssen ordnungsgemäß getrocknet werden, um die Anforderungen an Stapelung, Verpackung und Verwendung zu erfüllen. Als ein wesentlicher Bestandteil der Pulpmolding-Produktionslinie hat das Trocknungssystem für Eierkartons einen direkten Einfluss auf die Trocknungseffizienz und die Stabilität der Produktqualität.

Derzeit umfassen die üblichen Trocknungsverfahren für Eierbehälter natürliche Trocknung, Ziegelbrand-Trocknung und Metalltrocknung. Basierend auf dem Investitionsbudget des Kunden, der benötigten Produktionskapazität und den lokalen Klimabedingungen können wir geeignete Trocknungslösungen anbieten. Die Wahl der richtigen Trocknungsmethode verbessert nicht nur die Produktionseffizienz, sondern hilft auch, die Gesamtkosten der Produktion zu kontrollieren.

Natürliche Trocknung

- Merkmale: Geringe Investition, null Energieverbrauch, einfache Bedienung.

- Geeignet für: Regionen mit trockenem Klima, langen Sonnenstunden und viel Freifläche.

- Empfohlene Modelle: Einseitig Eierplattenmaschinen oder Kleinanlagen mit einer Kapazität von 1000–1500 Stück/Stunde.

- Am besten für: Neue Investoren, Kleinproduktion oder begrenzte Budgets.

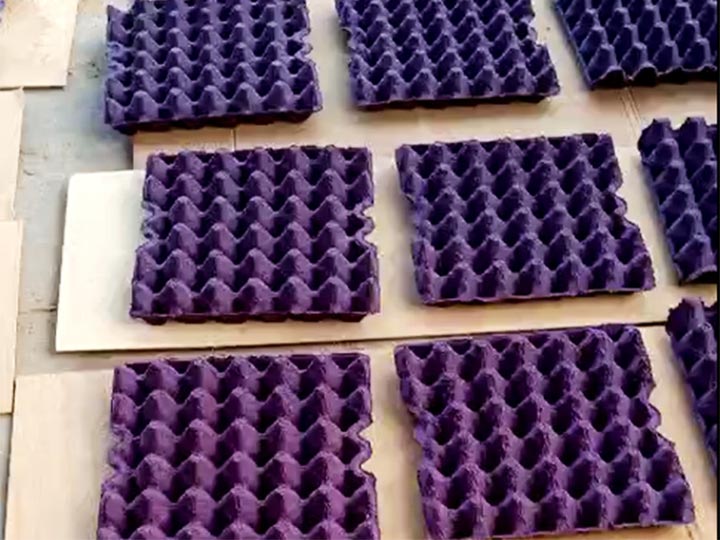

Natürliche Trocknung beinhaltet das manuelle Platzieren von nassen Tabletts auf sauberen Oberflächen oder Trockengestellen, um sie mit Sonnenlicht und natürlichem Wind an der Luft zu trocknen. Die Trocknung dauert typischerweise 4–6 Stunden. Diese Methode ist einfach und kostengünstig, ist jedoch stark wetterabhängig, was sie weniger ideal für eine kontinuierliche Produktion macht.

Trocknung im Ziegelofen

- Merkmale: Einfache Struktur, langlebig, kann bei jedem Wetter betrieben werden.

- Geeignet für: Gebiete mit weniger stabilen Klimabedingungen, aber niedrigen Arbeits- und Brennstoffkosten.

- Empfohlene Modelle: Mittelmaß Eierkarton Produktionslinien mit einer Kapazität von 2000–4000 Stück/Stunde.

- Am besten für: Kleine bis mittelgroße Fabriken mit grundlegender Infrastruktur.

Die Trocknung von Ziegelöfen erfolgt in einem aus Ziegeln gebauten Tunnel, der mit Holz, Kohle oder Gas beheizt wird. Nasse Tabletts werden auf Schienen oder Förderbändern hineinbewegt, wo sie durch die Zirkulation von heißer Luft getrocknet werden. Dies ist eine kosteneffiziente Methode für Anwender, die nach einer zuverlässigen Lösung mit überschaubaren Bau- und Betriebskosten suchen.

Metalltrocknungsanlage

- Merkmale: Hohe Automatisierung, präzise Temperaturkontrolle und schnelle Trocknungsgeschwindigkeit.

- Geeignet für: Großflächige, standardisierte Produktion mit kontinuierlichem Betrieb.

- Empfohlene Modelle: Vierseitige oder achtseitige Eierverpackungsmaschinen mit Kapazitäten von 4000–8000 Stück/Stunde.

- Am besten für: Große Fabriken oder exportorientierte Unternehmen mit stetiger Nachfrage.

Die Metalltrocknungsanlage besteht aus isolierten Metallpaneelen, mehrschichtigen Förderbändern und automatischen Temperaturregelungssystemen. Sie unterstützt mehrere Heizquellen wie Erdgas, Diesel oder Elektrizität.

Das System kann 24/7 betrieben werden und arbeitet synchron mit der Formmaschine, was Arbeitskräfte spart und die Gesamtproduktivität verbessert. Wir bieten maßgeschneiderte Designs basierend auf Ihrem Anlagenlayout und Ihren Produktionsbedürfnissen an.

Wie wählt man das richtige Trocknungssystem für Eiertrays aus?

Die Auswahl des richtigen Trocknungssystems für Eierverpackungen hängt von mehreren Schlüsselfaktoren ab:

- Produktionsvolumen: Höhere Ausgaben erfordern metallene Trocknungsanlagen mit höherer Effizienz.

- Klima und Raum: Sonnenreiche Gebiete mit Freiflächen eignen sich für die natürliche Trocknung.

- Budget und Betriebskosten: Natürliche oder Ziegeltrocknung eignet sich für niedrigere Budgets; für langfristige Effizienz wird Metalltrocknung empfohlen.

- Fabrikaufbau: Neue Anlagen können für Metalltrockner entworfen werden, während bestehende Ziegeltrockner aufgerüstet und wiederverwendet werden können.

Kontaktieren Sie uns für weitere Details zu Eierkartontrocknungssystemen

Das Trocknungssystem für Eierkartons ist ein entscheidender Schritt, der die Qualität und Effizienz der Eierkartonproduktion direkt beeinflusst. Wir bieten maßgeschneiderte Trocknungslösungen basierend auf Ihren Produktionsbedürfnissen, den Bedingungen im Werk und Ihrem Budget an. Wenn Sie planen, Ihre Eierkartonproduktionslinie zu starten oder aufzurüsten, zögern Sie nicht, uns für technische Unterstützung und Empfehlungen zu kontaktieren.