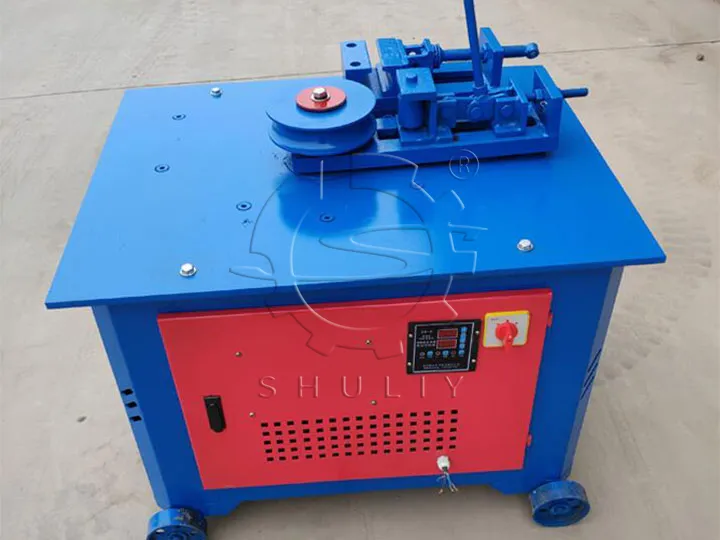

Bir CNC boru bükme makinesi, CNC veya hidrolik kontrol sistemi kullanarak bükme açılarını ve bükme yollarını hassas bir şekilde kontrol eden otomatik tüp şekillendirme makinesidir. Yüksek hassasiyetli metal borular ve tüplerin bükülmesi için tasarlanmıştır. Stabil performans ve yüksek otomasyon seviyesi ile bu makine, modern endüstrilerin tutarlılık, verimlilik ve üretim güvenilirliği konusundaki katı gereksinimlerini karşılar.

CNC Boru Bükme Makinesi Uygulamaları

CNC boru bükücüler, hassas ve dayanıklı boru bağlantıları gerektiren endüstrilerde yaygın olarak kullanılır, bunlar arasında:

- Otomotiv ve motosiklet egzoz sistemleri ve çerçeveleri

- Havacılık ve gemi yapım boru hattı sistemleri

- Petrokimya, elektrik enerjisi ve doğal gaz endüstrileri

- Kazanınlar, basınçlı kaplar ve endüstriyel boru hatları

- Fitness ekipmanları, spor malzemeleri ve metal mobilyalar

- Klima, soğutma ve paslanmaz çelik dekorasyon projeleri

Makine, yuvarlak borular, çelik borular, paslanmaz çelik borular, alüminyum borular ve belirli özel şekilli tüpler için uygundur.

CNC Boru Bükme Makinesi Çalışma Videosu

CNC Boru Bükme Makinesinin Temel Avantajları

Yüksek Bükme Doğruluğu ve Stabil Şekillendirme

CNC veya hidrolik kontrol sistemi ile donatılmıştır, bükme açı aralığı 0–180 dereceye ulaşır, yüksek tekrarlanabilirlik sağlar ve boru deformasyonu ile hurda oranını azaltır.

Yüksek Otomasyon Seviyesi

Besleme ve bükme işlemleri otomatik olarak tamamlanır, manuel emeği azaltır ve üretim verimliliğini artırır. Toplu üretim ve uzun vadeli operasyonlar için idealdir.

Farklı Boru Boyutları İçin Çoklu Modeller

Geniş bir model yelpazesi mevcuttur, 10 mm ile 100 mm arasında boru çaplarını kapsar ve farklı duvar kalınlığı kapasiteleri ile çeşitli işleme gereksinimlerini karşılar.

Kompakt Yapı ve Kolay Bakım

Makinenin kompakt düzeni, küçük ayak izi, dayanıklı bileşenler ve düşük bakım maliyetleri özellikleri vardır.

CNC Boru Bükme Makinesi Modelleri ve Teknik Parametreler

Elektrikli CNC Boru Bükme Makinesi Modelleri

| Modeli | Bükme Aralığı | Açı Aralığı | Ana Hız | Duvar Kalınlığı | Motor Gücü | Ağırlık |

| Model 38 | 10–24 mm | 0–180° | 20 rpm | 1–3 mm | 3 kW | 230 kg |

| 20–51 mm | 1–4 mm | 0–180° | 20 rpm | 260 kg | 3 kW | 30–76 mm |

| 16 rpm | 1–5 mm | 0–180° | 290 kg | 40–100 mm | 4 kW | 2–6 mm |

| 360 kg | Seyahat Hızı | 0–180° | 290 kg | Model-5 Hidrolik CNC | 5.5 kW | Yuvarlak tüp 10–50 mm / Çelik çubuk 4–28 mm |

Hidrolik CNC Boru Bükme Makinesi Modelleri

| Modeli | İşleme Kapasitesi | 12 m/dak | Motor Gücü | Makine Ağırlığı |

| 700 kg | Model-9 Hidrolik CNC | Yuvarlak tüp 10–60 mm / Çelik çubuk 4–32 mm | 3 kW | 3.8 kW |

| 900 kg | Model-11 Hidrolik CNC | Yuvarlak tüp 10–60 mm / Çelik çubuk 4–32 mm | Yuvarlak tüp 10–60 mm / Çelik çubuk 4–36 mm | 1050 kg |

| CNC boru bükme makinesi | CNC boru bükme makinesi | Yuvarlak tüp 10–60 mm / Çelik çubuk 4–32 mm | 5.5 kW | Bir CNC boru bükme makinesi seçerken aşağıdaki faktörleri göz önünde bulundurun: |

Doğru CNC Tüp Bükme Makinesi Nasıl Seçilir

Üretim verimliliği gereksinimleri (hız ve çıktı)

- Güç kaynağı ve montaj alanı

- CNC tüp bükme makinesinin fiyatı, bükme kapasitesi, tahrik tipi (elektrikli veya hidrolik) ve yapılandırmaya bağlıdır. Gerçek üretim ihtiyaçlarınıza uygun doğru modeli seçmek, toplam üretim maliyetlerini azaltmaya ve ürün kalitesini tutarlı tutmaya yardımcı olabilir.

- Düzenli, hassas ve dayanıklı bir CNC boru bükme makinesi arıyorsanız, lütfen bizimle iletişime geçin. Boru özellikleriniz, uygulama sektörü ve üretim gereksinimlerinize göre uygun modeli önerecek ve detaylı teknik parametreler ile rekabetçi bir teklif sunacağız.

- CNC boru bükme makineleri ile bu rebar işleme makinelerini birleştirerek, müşteriler daha eksiksiz ve verimli bir metal imalat hattı kurabilir, inşaat projeleri, prefabrik bileşenler ve endüstriyel üretim uygulamaları için uygundur.

- Satış sonrası servis ve teknik destek

CNC Boru Bükme Makinesi Fiyatları ve Satın Alma Rehberi

Bir CNC boru bükme makinesinin fiyatı, bükme kapasitesi, sürücü tipi (elektrik veya hidrolik) ve konfigürasyona bağlı olarak değişir. Gerçek üretim ihtiyaçlarınıza uygun doğru modeli seçmek, toplam üretim maliyetlerini azaltmaya yardımcı olabilir ve tutarlı ürün kalitesini sağlar.

Eğer stabil, hassas ve dayanıklı bir CNC boru bükme makinesi arıyorsanız, lütfen bizimle iletişime geçin. Boru özellikleriniz, uygulama sektörü ve üretim gereksinimlerinize göre uygun bir model önerecek ve detaylı teknik parametreler ile rekabetçi bir teklif sunacağız.

Tam Metal Şekillendirme Çözümleri için İlgili Rebar İşleme Makineleri

CNC boru bükme makinelerine ek olarak, farklı metal şekillendirme ve inşaat ihtiyaçlarını karşılamak için tam donanımlı bir çelik çubuk işleme ekipmanı yelpazesi de sunuyoruz. Bükmeden önce ham çelik çubukların düzleştirilmesi için, çelik çubuk düzleştirme makinesi yaygın olarak kullanılır ve işlem doğruluğunu ve verimliliği artırır. Dairesel veya spiral şekiller gerektiğinde, çelik çubuk halka yapma makinesi otomatik olarak çelik çubukları tutarlı halkalara dönüştürebilir. Açı bükme ve şekil verme işlemleri için, çelik çubuk bükme makinesi, perçinler, çerçeveler ve özelleştirilmiş bükme açıları üretmek için idealdir.

CNC boru bükme makinelerini bu demir çelik işleme makineleriyle birleştirerek, müşteriler daha eksiksiz ve verimli bir metal imalat hattı kurabilirler; bu, inşaat projeleri, prefabrik bileşenler ve endüstriyel üretim uygulamaları için uygundur.